With the enhancement of environmental awareness and the increasing importance of resource recycling, recycled rubber as an environmentally friendly recycled material has received extensive attention from rubber product enterprises. EPDM recycled rubber is a small category of recycled rubber products, using EPDM head glue and sealing strip as the main raw material, after classification and crushing twin screw 80 mesh double channel filtration molding, can retain the original molecular weight and rubber chain structure more than 90%, the use of patented segmented desulfurization method production of ethylene propylene regenerated rubber has low price, environmental protection and tasteless characteristics, can replace ethylene propylene rubber production of civil rubber products. Hongyun EPDM reclaimed rubber has the following two characteristics:

1. Low price. Compared with the price of virgin EPDM rubber, the price of EPDM recycled rubber is lower, which can greatly reduce the cost of raw materials and improve the market competitiveness of products such as EPDM rubber pads.

2. Environmental protection and tasteless. HY EPDM recycled rubber in the production process after a series of treatments to effectively remove the odor in the rubber, the selected raw materials can pass the RoHs2.0 environmental protection testing directive, for export to EU rubber products can reduce the cost of raw materials.

Hongyun ethylene propylene recycled rubber production sealing rubber gasket reference vulcanization formula: HY grade 1 EPDM recycled rubber 25kg, N550 carbon black 1.5kg, rubber reinforcing agent 10kg, paraffin oil 2kg, paraffin wax 0.2kg, zinc oxide 0.6kg, polyethylene glycol 0.4kg, CZ accelerator 0.15kg, DM accelerator 0.13kg, TMTD accelerator 0.03kg, sulfur 0.3kg, active agent 0.1kg, vulcanization temperature 160-170 °C, vulcanization time according to the thickness is determined. By properly matching the dosage of additives, ethylene propylene reclaimed sealing rubber gaskets with good performance can be produced.

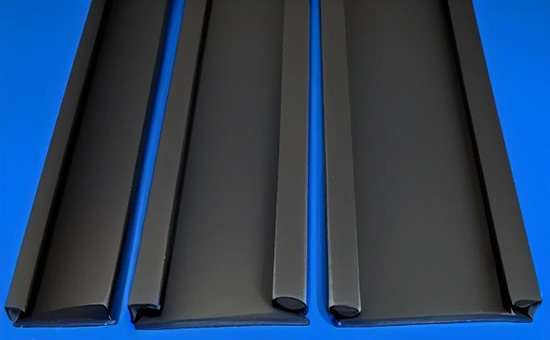

The processing process of EPDM recycled rubber production sealing dustproof rubber pad YY23-807 needs to pay attention to the following 3 points:

1. Choose high-quality EPDM recycled rubber. The quality of recycled rubber must be stable, and it can be purchased in small batches for many times and quality inspection to determine stability.

2. Pay attention to the feeding sequence and parking time during the processing process of mixed rubber. EPDM rubber is not easy to scorch, many technicians are accustomed to mixer plus accelerator, this way is easy to scorch or spray in summer, it is recommended to open the mill to add accelerator, vulcanizing agent and strictly control the dosage.

3. The vulcanization temperature and time are accurate. In order to fully crosslink the ethylene propylene recycled rubber during the vulcanization process to achieve the ideal physical properties, it is recommended to conduct a vulcanization test to observe T10 and T90 and the vulcanization curve to determine the optimal vulcanization time and temperature.

EPDM rubber mat mixed with EPDM recycled rubber is a low-cost production method, which can not only reduce the production cost of EPDM pad, but also reduce the consumption of resources using virgin EPDM rubber. In the production and processing process, it is necessary to pay attention to the amount of rubber and auxiliary materials and the feeding sequence, and constantly optimize the process to ensure that the product has better physical property indicators. The application range of EPDM recycled rubber in ethylene propylene rubber products is broad, and the current rubber market has higher and higher requirements for cost performance, and rubber products mixed with EPDM recycled rubber will usher in a larger market share.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits