EPDM reclaimed rubber has excellent performance characteristics such as high and low temperature resistance, anti-aging, high insulation, etc. It can not only replace EPDM rubber and EPDM original rubber or other general rubbers such as natural rubber and styrene-butadiene rubber. Reduce the production cost of rubber products; other special rubbers and plastics such as butyl rubber, butyl rubber and polyethylene, polypropylene and other plastics can also be mixed with an appropriate proportion of EPDM reclaimed rubber to further improve the comprehensive performance of rubber and plastic products.

6. Combined use of butyl rubber and EPDM reclaimed rubber

Butyl rubber is synthesized from isobutylene and a small amount of isoprene. It has excellent air tightness and good chemical and thermal stability. It is widely used in the manufacture of tire inner tubes, building waterproof materials, and heat-resistant rubber. Butyl rubber has good compatibility with EPDM reclaimed rubber 2ELYY85. Adding an appropriate amount of EPDM reclaimed rubber to butyl rubber can significantly improve the aging resistance, wear resistance and compression resistance of butyl rubber. Permanent deformation, improve anti-vulcanization resistance of butyl compounds.

In actual production, a proper amount of EPDM reclaimed rubber is used in the butyl rubber inner tube formula. The semi-finished inner tube has good stiffness, excellent aging resistance, and a high performance retention rate after aging. The butyl inner tube has tensile stress and hardness after high temperature aging. It has been increased, and the elasticity of the vulcanizate has been significantly improved.

7. Combined use of neoprene rubber and EPDM reclaimed rubber

Neoprene rubber is made of chloroprene as the main raw material by α-polymerization. It has good physical and mechanical properties, oil resistance, heat resistance, flame resistance, sunlight resistance, ozone resistance, acid and alkali resistance, and is widely used in the production of transmission belts, conveyor belts, Wire and cable, oil-resistant rubber sheet, oil-resistant rubber hose, sealing material, adhesive, etc. In actual production, neoprene can be used together with an appropriate amount of EPDM reclaimed rubber to improve the compression deformation, low temperature resistance, electrical properties and color stability of neoprene.

8. Nitrile rubber and EPDM reclaimed rubber are used together

Nitrile rubber, which is polymerized from acrylonitrile and butadiene monomers, has excellent oil resistance, good heat resistance, wear resistance, and strong adhesion. It is widely used in the production of oil-resistant gaskets, gaskets, and casings. , flexible packaging, flexible hose, printing and dyeing rubber rollers, cable rubber materials, etc. The use of an appropriate amount of EPDM reclaimed rubber in the rubber products with nitrile rubber as the main raw material can significantly improve the weather resistance, ozone resistance, low temperature resistance, etc. electrical properties.

9. EPDM reclaimed rubber for plastic modification

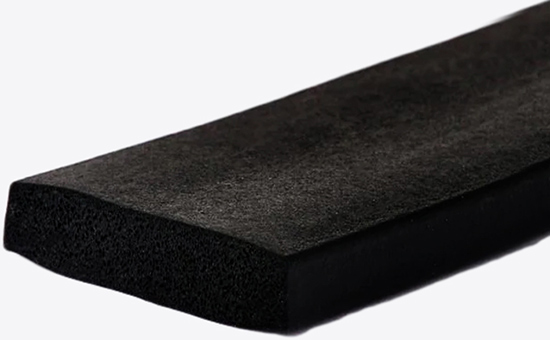

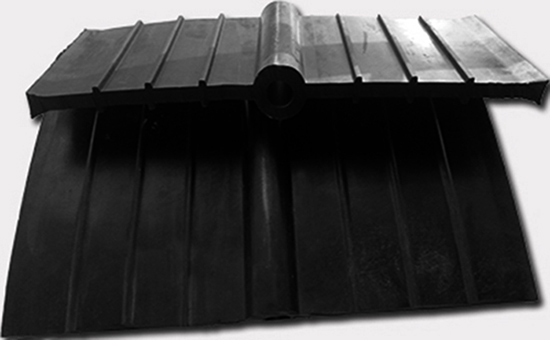

EPDM reclaimed rubber can not only be mixed into various rubber products, but also used in plastic modification, and used together with polyethylene and polypropylene to improve the impact resistance and toughness of plastics. In actual production, EPDM reclaimed rubber can be blended with low-density polyethylene to prepare waterstop products with low cost and long service life; blended with polypropylene, the blended material has high mechanical strength, weather resistance and heat resistance. Aging, chemical corrosion resistance, ozone resistance. Polyvinyl chloride can also be blended with EPDM reclaimed rubber. Appropriate use of compatibilizers can significantly improve the polymer compatibility effect, improve the impact resistance of PVC, the elasticity of soft products, and low temperature resistance.

EPDM reclaimed rubber has excellent high temperature resistance, weather resistance and ozone resistance, its compatibility with other rubber and plastic materials is better than that of EPDM original rubber, and its price is much lower than that of original rubber, so it can replace a certain proportion of EPDM rubber Ethylene propylene rubber is blended with EPDM or other rubber and plastic materials to further improve the comprehensive performance of rubber products while reducing costs. Later, the editor will continue to share with you the specific application of EPDM reclaimed rubber in rubber and plastic products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits