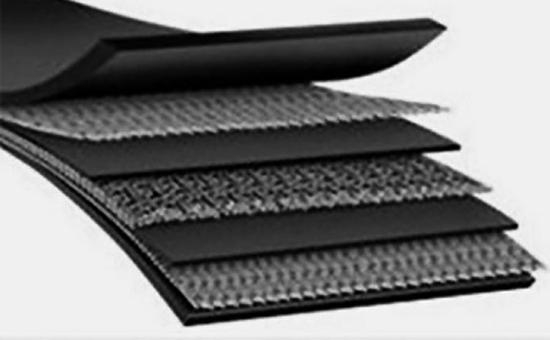

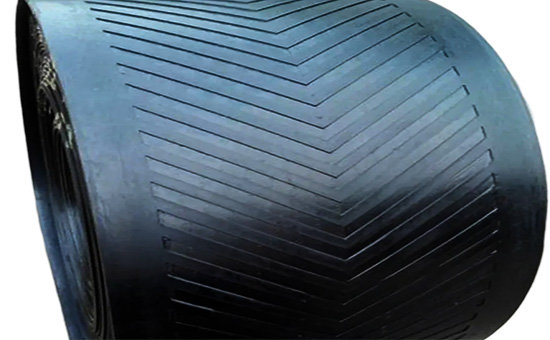

The conveyor belt covering rubber requires the covering rubber to have high tensile strength, elasticity, wear resistance, tear resistance, heat resistance and ozone resistance, sunlight resistance, heat aging resistance and microbial erosion resistance, etc., generally based on natural rubber, and the appropriate use of secondary brand natural rubber can effectively reduce the cost of raw materials.

1. The technique of ordinary fabric core conveyor belt covering glue mixed with secondary brand natural rubber

The general purpose fabric core conveyor belt is subjected to the impact of the material, wear, multiple bending and deformation, temperature changes, the action of the atmosphere (ozone, the action of sunlight) and the erosion of microorganisms, etc., and the elasticity and strength of the rubber material should be strictly required, and the rubber content should be controlled at 50%-55% when the conveyor belt is covered with natural rubber E5LYY421 as the main raw material; Secondary natural rubber can replace genuine natural rubber in whole or in part to produce ordinary fabric core conveyor belt covering rubber, and if necessary, it can be mixed with some styrene-butadiene rubber and butadiene rubber to further improve the process performance of the rubber material and reduce costs.

2. Key points of the design of the general fabric core conveyor belt covering rubber formula mixed with secondary brand natural rubber

(1) Vulcanization system

When sub-brand natural rubber is used with genuine natural rubber, styrene-butadiene rubber or butadiene rubber to produce general-purpose fabric core conveyor belt covering glue, the sulfur-accelerator system is mostly used; The amount of sulfur is generally controlled among 2.5-3 parts when the secondary brand natural rubber is used together with styrene-butadiene rubber, and the sulfur amount is controlled among 1.5-2.5 parts when the secondary brand natural rubber is used together with styrene-butadiene rubber, and when the secondary brand natural rubber is used together with butadiene rubber, the sulfur amount is controlled among 1.5-2 parts.

It is recommended to use thiazole accelerator with sulfur for general purpose fabric core conveyor belt covering glue, and it is appropriate to use accelerator M and accelerator DM together, so as to ensure a certain vulcanization speed and a long scorching time. The fabric core conveyor belt covering rubber containing styrene-butadiene rubber selects after-effect accelerators, such as accelerators CZ, DZ, etc.

(2) Reinforce the filling system

When sub-brand natural rubber and genuine natural rubber, styrene-butadiene rubber or butadiene rubber are used to produce general-purpose fabric core conveyor belt covering glue, the reinforcement agent is mostly medium and super wear-resistant furnace black, high wear furnace black, general furnace black and semi-reinforced furnace black, etc., and the dosage is controlled at 40-60 parts; Appropriate amount of calcium carbonate or activated clay is added to reduce the cost of glue.

(3) Soften the system

Secondary brand natural rubber and genuine natural rubber, styrene-butadiene rubber or butadiene rubber are used to produce general-purpose fabric core conveyor belt covering glue, reasonable use of softeners can improve the elasticity of the rubber material, improve processing performance, commonly used softeners are pine tar, liquid or solid coumaron, three-line oil, six-line oil, engine oil and heavy oil, etc.

(4) Anti-aging system

When sub-brand natural rubber and genuine natural rubber, styrene-butadiene rubber or butadiene rubber are used to produce general-purpose fabric core conveyor belt covering glue, the appropriate use of p-phenylenediamine anti-aging agents can effectively prolong the aging time, and the dosage is controlled at 1.0-2.0 parts; Commonly used p-phenylenediamine anti-aging agents include anti-aging agents 4010, 4010NA, 4020, etc.

The rational use of sub-brand natural rubber in the general purpose fabric core conveyor belt covering rubber can effectively reduce production costs. In actual production, sub-brand natural rubber can also be used to replace some genuine natural rubber in rubber conveyor belt buffer adhesive and cloth rubber, reducing production costs, and discussing related issues with you later.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits