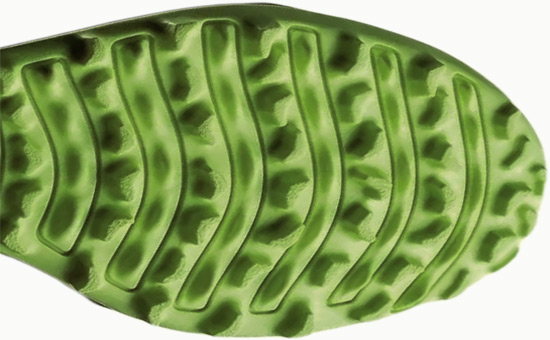

Rubber soles of rubber shoes have high requirements for wear resistance, bending resistance, flexibility, elasticity and strength. The rubber material has good flexibility, small shrinkage and good adhesion. It is generally processed with natural rubber as the main raw material, or it is used in combination with styrene butadiene rubber, cis polybutadiene rubber or recycled rubber in a proper proportion. In actual production, natural rubber/recycled rubber can not only be used to produce black rubber soles, but also can produce various colored rubber soles, such as green rubber soles, to reduce manufacturing costs on the premise of ensuring product quality.

1. Natural rubber/styrene butadiene rubber production military green rubber outsole reference formula

70 portions of natural rubber, 30 portions of styrene butadiene rubber, 10 portions of zinc oxide, 7 portions of stearic acid, 1 portion of antioxidant D, 65 portions of aluminum hydroxide, 15 portions of magnesium carbonate, 8 portions of coumarone resin, 7 portions of engine oil, 5 portions of lemon yellow, 0.1 portions of carbon black N330, 7 portions of clay, 0.5 portions of accelerator CZ, 1 portion of accelerator D, 1 portion of accelerator M, and 2.2 portions of sulfur; Total: 229.8 copies.

2. Natural rubber/polybutadiene rubber/recycled rubber production military green rubber outsole reference formula

50 parts of natural rubber, 50 parts of polybutadiene rubber, 25 parts of recycled rubber, 5 parts of zinc oxide, 3 parts of stearic acid, 0.5 parts of antioxidant MB, 0.5 parts of antioxidant 4010, 75 parts of clay, 2 parts of chrome yellow, 0.1 parts of pigment green, 0.1 parts of carbon black N660, 26 parts of engine oil, 3 parts of petroleum jelly, 1.1 parts of accelerator D, 1.5 parts of promoter NOBS, 1.6 parts of sulfur; Total: 244.4 copies.

3. Reference formula of grass green rubber outsole produced by natural rubber/recycled rubber

100 portions of natural rubber, 25 portions of light colored recycled rubber, 5 portions of zinc oxide, 3 portions of stearic acid, 0.8 portions of antioxidant MB, 0.2 portions of antioxidant H, 0.3 portions of paraffin wax, 75 portions of clay, 0.1 portions of carbon black N660, 0.1 portions of pigment green, 23 portions of engine oil, 3 portions of pine tar, 3 portions of petroleum jelly, 1.5 portions of accelerator M, 0.5 portions of accelerator TMTD, and 2.5 portions of sulfur; Total: 243 copies.

The latex reclaimed rubber and tire reclaimed rubber in the reclaimed rubber products have good compatibility with natural rubber and can be used with natural rubber to produce rubber products. Light colored reclaimed rubber, such as white latex reclaimed rubber 2ELYY1028, can be used to produce various light white and color rubber products. The rubber outsole directly contacts the ground and frequently bears friction, pressure and bending. When the green rubber outsole is produced with natural rubber as the main raw material, it can further extend the service life of the rubber outsole while reducing the cost by selecting the appropriate type of recycled rubber according to the actual demand, reasonably determining the proportion of recycled rubber, and properly adjusting the formula of the rubber outsole containing recycled rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits