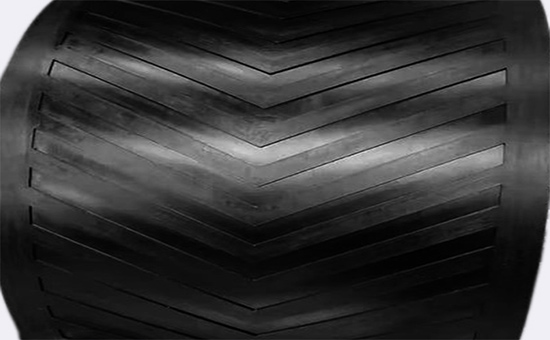

The middle interlayer of nylon rubber conveyor belt is nylon canvas, which has the characteristics of thin belt body, high strength, impact resistance, strong adhesion, and resistance to flexing. High-speed material transportation, in which the quality of nylon canvas rubber directly affects the performance and life of rubber conveyor belts. Today, Xiaobian will share with you three nylon rubber conveyor belts with natural rubber as the main raw material, mixed with styrene-butadiene rubber and tire reclaimed rubber. Reference formula for rubbing glue.

1. Nylon conveyor belt rubbing formula for natural rubber/styrene-butadiene rubber production

50 parts of natural rubber, 50 parts of oil-extended styrene-butadiene rubber, 5 parts of zinc oxide, 3 parts of stearic acid, 1 part of antioxidant, 28 parts of carbon black, 12 parts of white carbon black, 12 parts of aromatic oil, 1.5 parts of rosin, 6 parts of hydroquinone, 1.6 parts of accelerator H, 1.1 part of accelerator CZ, 0.3 part of accelerator DM, 3 parts of sulfur; total: 174.5 parts.

2. Nylon conveyor belt rubbing formula for natural rubber/styrene-butadiene rubber/tire reclaimed rubber

50 parts of natural rubber, 40 parts of oil-extended styrene-butadiene rubber, 20 parts of tire reclaimed rubber, 10 parts of zinc oxide, 3 parts of stearic acid, 1 part of anti-aging agent, 25 parts of carbon black, 12 parts of white carbon black, 6 parts of adhesive parts, 10 parts of pine tar, 2 parts of accelerator CZ, 1.5 parts of accelerator H, 2.3 parts of sulfur; total: 182.8 parts.

3. Nylon conveyor belt rubbing formula for natural rubber/tire reclaimed rubber production

80 parts of natural rubber, 40 parts of tire reclaimed rubber, 10 parts of zinc oxide, 3 parts of stearic acid, 1 part of antioxidant, 25 parts of carbon black, 12 parts of silica, 6 parts of binder, 10 parts of pine tar, accelerator 1.5 parts of agent CZ, 1.5 parts of accelerator H, 2.5 parts of sulfur; total: 192.5 parts.

The main function of rubbing the cloth layer of the nylon rubber conveyor belt is to bond the nylon belt core cloth layer into a whole, and the rubber material is required to have good adhesion performance and fatigue resistance. In actual production, the nylon conveyor belt canvas rubbing rubber with natural rubber 2ELYY512 as the main raw material can be mixed with styrene-butadiene rubber and tire reclaimed rubber in an appropriate amount; and the amount of coumarone and petroleum resin can be appropriately increased to improve the cloth layer rubbing adhesive force. Nylon conveyor belt rubbing rubber containing tire reclaimed rubber is generally vulcanized with sulfur and reinforced with semi-reinforced carbon black.

When using tire reclaimed rubber to produce nylon rubber conveyor belt rubbing, it is recommended to select appropriate tire reclaimed rubber according to the requirements of rubbing technical indicators, and properly adjust the coordination and production process conditions to further optimize the quality of finished products while reducing costs. The editor will continue to discuss related issues with you later.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits