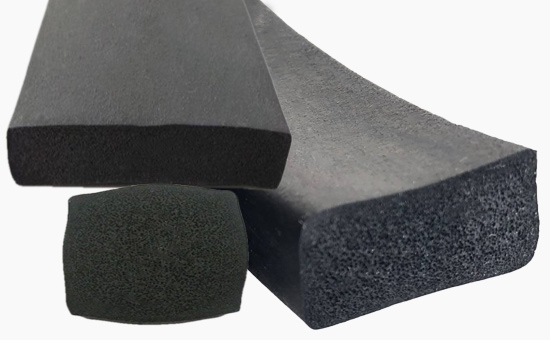

The foamed rubber products processed with natural rubber as the main raw material have light texture, good elasticity and high mechanical strength, and are suitable for various use occasions. However, the price of natural rubber is high and the price fluctuates greatly. The general economic situation, international import and export policies, and climate disasters (drought, diseases and insect pests, etc.) in rubber production areas will all affect the price of natural rubber. Therefore, many manufacturers of natural rubber foam products hope to use reclaimed rubber in the formulation of foam products, which can reduce the cost of raw materials and secondly, can better control the cost.

1. Latex recycled rubber

Latex reclaimed rubber is a natural rubber waste rubber cup, rubber thread or waste natural rubber products, waste latex products processed reclaimed rubber, the main purpose is to replace natural rubber to reduce raw material costs. Latex reclaimed rubber has a high effective hydrocarbon content, and various indicators are close to natural rubber. It can directly replace natural rubber or be used in conjunction with natural rubber to produce foamed rubber products, significantly reducing raw material costs. In actual production, latex reclaimed rubber is mostly used to prepare high-performance natural rubber foam products.

2. Tire recycled rubber

Processing waste rubber tires into reclaimed rubber is one of the main ways to achieve waste tire recycling. The main components of tire reclaimed rubber are natural rubber, general-purpose synthetic rubber (styrene butadiene rubber, butadiene rubber) and carbon black. It has good compatibility with natural rubber. It can be used together with natural rubber to prepare foam rubber products, reducing more Raw material costs. The large amount of tire reclaimed rubber 2LLYY714 used in natural rubber foam products to reduce raw material costs is better than the natural rubber in which a large amount of low-cost inorganic fillers are used to produce foam products, and the comprehensive index of finished products is higher.

3. Shoe sole recycled rubber

Compared with tire reclaimed rubber, the price of reclaimed rubber sole is lower, and the use of a small amount of natural rubber to produce low-grade foamed rubber products can achieve better economic benefits. In actual production, about 100 parts of natural rubber can add about 600-800 parts of reclaimed rubber. In addition, many manufacturers choose to use tire recycled rubber and shoe sole recycled rubber together to further reduce costs while ensuring the performance of natural rubber foam products.

In actual production, different varieties of reclaimed rubber have different performance indicators, and the specific needs of natural rubber foam products in different use occasions are very different. Rubber product manufacturers need to determine the amount of reclaimed rubber according to actual needs to ensure foaming. The rubber products are foamed evenly and fully while increasing the amount of reclaimed rubber as much as possible. The use of reclaimed rubber in foam rubber products can also improve the processing performance of rubber compounds to a certain extent, produce foam rubber products with higher cost performance, and improve the market competitiveness and economic benefits of products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits