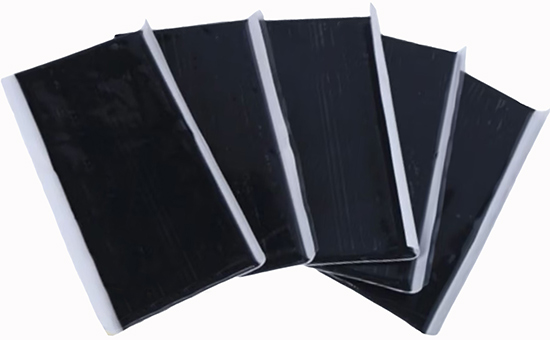

Butyl rubber damping sheet is made of butyl rubber as the main material, mainly used to reduce vibration and noise rubber products, with excellent elastic and damping properties, in automobiles, construction, machinery and other occasions that require shock absorption and sound insulation has a wide range of applications. Butyl reclaimed rubber is made from the desulfurization and regeneration of waste butyl rubber products (mainly waste butyl inner tubes), which is mainly used to replace butyl rubber and reduce the cost of raw materials. In actual production, can butyl reclaimed rubber be used in the production of butyl rubber damping sheets? How can damping sheets reduce costs more without sacrificing the quality of the finished product?

1. The advantages of using butyl reclaimed rubber in rubber damping sheets

Butyl reclaimed rubber retains many characteristics of butyl original rubber, and high-quality butyl reclaimed rubber has the characteristics of good air tightness, high strength, good elasticity, heat resistance, aging resistance, chemical resistance, shock absorption, etc., which can meet the basic performance requirements of products for the production of rubber damping sheets. Compared with butyl rubber, butyl reclaimed rubber has low price, good processing performance, and relatively better compatibility with other rubber and plastics, which can not only reduce the cost of raw materials but also improve the processing performance of rubber in the production of rubber damping sheets.

2. The application of butyl reclaimed rubber in rubber damping sheets

There are three main ways to apply butyl reclaimed rubber in the production of rubber damping sheets:

(1) The price of rubber damping sheets produced by using butyl reclaimed rubber alone is much lower than that of butyl original rubber, and it can effectively reduce the cost of raw materials when directly used in the production of damping sheets. (2) Butyl reclaimed rubber and butyl rubber 2SLYY126 rubber are used together to produce rubber damping sheets, which can not only reduce the cost of raw materials, but also improve the processing performance of butyl rubber. (3) Butyl reclaimed rubber is blended with PVC to prepare rubber damping sheet materials, and it is recommended to use CPE to modify PVC, and thermoplastic elastomers have good damping properties, mechanical properties, heat resistance, flame retardancy, etc.

3. Application skills of butyl reclaimed rubber in rubber damping sheets

When using butyl reclaimed rubber alone or butyl reclaimed rubber and original rubber, and blending with PVC to prepare butyl rubber damping sheets, it is necessary to choose appropriate butyl reclaimed rubber, and meet the performance requirements of different rubber damping sheets by adjusting the combined ratio of butyl reclaimed rubber and butyl rubber, butyl reclaimed rubber and PVC; If necessary, the variety and dosage of reinforcing agent and filler in the formula can be adjusted, and the butyl reclaimed rubber/PVC blending can be modified to optimize the rubber and rubber and plastic formulas, and further improve the comprehensive index of rubber damping sheets while reducing costs.

The mixing ratio of butyl reclaimed rubber in rubber damping sheet is uncertain, and the low mixing ratio of 10% - 20% is mainly used to maintain the original properties of butyl rubber; A medium blending ratio of 30% to 40% can reduce costs while maintaining performance; When the proportion of butyl reclaimed rubber is more than 50%, more products with lower mechanical performance requirements can be produced to reduce the cost of more raw materials.

In actual production, when using butyl reclaimed rubber to reduce the cost of rubber damping sheets, you can also improve the quality of finished damping sheets by adjusting the variety and dosage of compounding agents such as formula vulcanization system, reinforcing filling system, softening system, etc., and the follow-up editor will continue to share related issues with you.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits