In the rubber industry, butyl reclaimed rubber is widely used in the production of butyl rubber products due to its excellent air tightness and low price, and can be used alone or in combination with butyl rubber. In order to meet the physical property requirements of more butyl rubber products, it is particularly important to optimize the static mechanical properties of butyl reclaimed rubber vulcanized rubber. The static mechanical properties of butyl reclaimed rubber refer to the properties of reclaimed rubber when it is subjected to external force in a static state.

Butyl reclaimed rubber vulcanized rubber has two properties of strength and elastic relaxation under static load, and the performance index of strength is the ability of butyl reclaimed rubber vulcanized rubber to resist failure under mechanical action, tensile strength and tear strength characterization; Elastic relaxation properties are expressed in terms of hardness, creep and stress relaxation indicators. In actual production, the tensile strength of reclaimed rubber vulcanized rubber not only affects its tensile ability, but also closely related to wear resistance and impact resistance.

1. The main indicators of static mechanical properties of butyl reclaimed rubber vulcanized rubber

(1) Tensile strength: refers to the maximum stress that the rubber material can withstand during the tensile process until it breaks. The tensile strength of butyl reclaimed rubber vulcanized rubber is closely related to the service life of the product. For example, when butyl reclaimed rubber and ethylene propylene rubber are used together to produce heat-resistant conveyor belt covering rubber, the wear resistance of the conveyor belt covering rubber is proportional to the tensile strength of the reclaimed rubber vulcanized rubber; When butyl reclaimed rubber is produced to produce impact-resistant rubber products, the durability of the finished product will increase with the improvement of the strength of the reclaimed rubber vulcanized rubber.

(2) Tear strength: the ability of rubber to resist tearing. The tear strength of the vulcanized rubber is usually proportional to the tensile strength, and increases with the decrease of elongation at break and the increase of hardness during vulcanization. Formulation and process factors have a greater impact on the tear strength of vulcanized rubber than on tensile strength.

(3) Hardness: It measures the ability of rubber to resist deformation, reflecting the elastic modulus of vulcanized rubber when it is slightly deformed.

2. Techniques for optimizing the static mechanical properties of butyl reclaimed rubber vulcanized rubber by adjusting the formula

(1) Optimization of vulcanization system of reclaimed rubber

The vulcanization system has an important impact on the physical and mechanical properties of the reclaimed rubber vulcanized rubber. Generally, the increase of the amount of sulfur and co-accelerator will lead to the reduction of the tensile strength of the reclaimed rubber vulcanized rubber, and the increase of the amount of main accelerator can increase the elongation at break. The elongation at break of butyl reclaimed rubber vulcanized rubber generally decreases with the increase of sulfur and the amount of main accelerator, and increases with the increase of the amount of DM of the auxiliary accelerator.

(2) Optimization of reclaimed rubber reinforcement filling system

The reinforcing system has a great influence on the static mechanical properties of butyl reclaimed rubber vulcanized rubber, and the commonly used reinforcing agents are carbon black, white carbon black, and fillers are clay and calcium carbonate.

The type and amount of carbon black added have a significant effect on the physical and mechanical properties of butyl reclaimed rubber vulcanized rubber. In general, fine particle furnace carbon blacks, tank carbon blacks, and silica are the best at enhancing tear resistance. With the increase of carbon black addition, the tensile strength of butyl reclaimed rubber 2SLYY1114 vulcanized rubber decreased slightly, the tensile stress increased with the increase of carbon black addition, the elongation at break decreased with the increase of carbon black addition, the hardness increased with the increase of carbon black addition, and its elasticity decreased. The performance of the compression set deteriorates with the increase of carbon black addition.

Calcium carbonate and clay have a certain effect on improving the hardness and tensile strength of butyl reclaimed rubber vulcanized rubber, but at the same time, they may affect the elongation of vulcanized rubber.

(3) Optimization of reclaimed rubber softening system: the use of softeners and plasticizers will affect the mechanical properties of vulcanized rubber while improving the processing performance of butyl reclaimed rubber, such as the use of operating oil will lead to the reduction of strength and the increase of elongation.

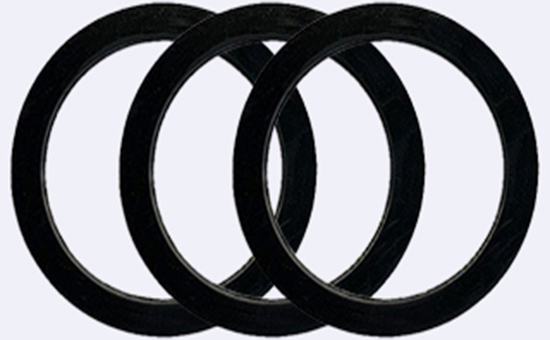

Butyl reclaimed rubber is a recycled, treated and reprocessed rubber material, which is widely used in the production of tires, seals, shock absorbers and other products. By optimizing the formulation and process of butyl reclaimed rubber vulcanized rubber, its static mechanical properties can be significantly improved, including the selection of appropriate vulcanization systems, reinforcing agents and plasticizers, as well as adjusting their dosages. Through these measures, it is possible to produce better and more reliable butyl rubber products to meet the growing market demand and improve economic benefits.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits