Butyl reclaimed rubber is made of waste butyl rubber inner tube, butyl glue tire vulcanized capsule or butyl rubber bottle stopper and other products as raw materials, processed by sorting, crushing, desulfurization, filtration and other processes, with low price, good air tightness, heat resistance and chemical corrosion resistance, which is a cost-effective recycled rubber resource in the rubber products industry. However, if butyl reclaimed rubber is not used well, it will not only fail to reduce costs, but also lead to the performance of rubber products cannot meet the demand, so how to use butyl reclaimed rubber best?

1. Application field of butyl reclaimed rubber

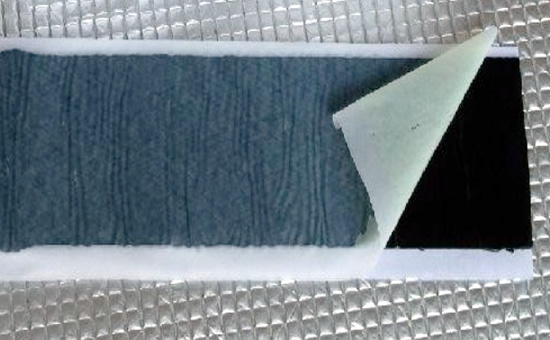

Butyl reclaimed rubber has the basic performance characteristics of butyl rubber, so general butyl rubber products can use butyl reclaimed rubber, and the following categories are commonly used. (1) Butyl reclaimed rubber in tire manufacturing can be used to produce inner tubes of tires, inner liners of tubeless tires, vulcanized capsules, etc.; (2) In the construction industry, butyl reclaimed rubber 2SLYY112 can be used to produce waterproof membranes, rubber dams, sealing materials, etc.; (3) Butyl reclaimed rubber in rubber sealing products can be used to manufacture various sealing gaskets, sealing strips, sealing rings, etc.; (4) Butyl reclaimed rubber in shock absorbing materials can be used to produce shock absorbers, sound insulation panels, soundproof materials, etc.; Hose tape can be used to make heat-resistant hoses, chemical-resistant tapes, etc.; (5) Butyl reclaimed rubber in insulating materials can be used to produce insulating layers of wires and cables, cable head films, etc.

Butyl reclaimed rubber can also be used to produce printing rubber rollers, textile rubber rollers, anti-corrosion linings, sponge rubber, etc. These applications make full use of the heat resistance, aging resistance, chemical resistance and good air tightness of butyl reclaimed rubber, and are also favored for their cost-effectiveness.

2. Application method and addition ratio of butyl reclaimed rubber

The use of butyl reclaimed rubber can be adjusted according to different needs to achieve the best balance of performance and cost. In practical applications, butyl reclaimed rubber can be used alone, or combined with butyl rubber and EPDM rubber to produce tire inner tubes, inner liners, rubber sealing strips, heat-resistant hoses, etc. The dosage of butyl reclaimed rubber needs to be determined according to the physical properties of butyl reclaimed rubber, specific product requirements and performance indicators, for example, butyl reclaimed rubber can be completely used in bicycle inner tubes to ensure that the performance of the final product meets the application requirements.

3. Design of butyl reclaimed rubber vulcanization formula

When using butyl reclaimed rubber to produce rubber products, the formula design directly affects the quality and cost of the finished product. In general, the commonly used vulcanization systems for butyl reclaimed rubber products include sulfur, resin, etc., to meet different product needs; Carbon black, silica, talc, etc. are commonly used in the reinforcing filling system to improve the performance of the product; Paraffin oil and ester plasticizers are commonly used as softeners, and the processing technology and product performance of butyl reclaimed rubber can be improved by adjusting the dosage.

In addition, when using butyl reclaimed rubber to produce sponge rubber, it is also necessary to pay attention to the cooperation among the vulcanization system and the foaming system, so that the vulcanization speed matches the foaming speed to ensure product quality.

When using butyl reclaimed rubber to produce rubber products, we must choose reclaimed rubber products, choose the appropriate mixing ratio, and reasonably design the formula, so as to effectively reduce costs and improve the market competitiveness of butyl rubber products while ensuring product quality.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits