Butyl reclaimed rubber has excellent air tightness, water tightness, heat resistance, aging resistance, chemical resistance and other properties, good shock absorption, insulation, damping performance, retains the basic performance characteristics of butyl rubber, can be used alone or with butyl rubber, ethylene propylene rubber to produce rubber products, effectively reduce the cost of raw materials. In the production of butyl reclaimed rubber products, the vulcanization system has an important impact on the quality of the finished product, this article shares with you the typical vulcanization system and vulcanized rubber characteristics of butyl reclaimed rubber.

1. Sulfur vulcanization system and vulcanized rubber characteristics of butyl reclaimed rubber

Sulfur is the most commonly used vulcanizing agent in rubber products, and when butyl reclaimed rubber is sulfurized, high-efficiency accelerators are mostly used to match sulfur, which requires high temperature and long-term vulcanization. The sulfur vulcanization system of butyl reclaimed rubber products is commonly used as the first accelerator of thiuram and dithiocarbamate, thiazole or quaat as the second accelerator, and zinc oxide and stearic acid are used as active agents. For example, 60% accelerator TMTD and 40% accelerator M are used together, activated by zinc oxide, the vulcanization speed is medium during vulcanization, and the processing performance of butyl reclaimed rubber and the physical and mechanical properties of vulcanized rubber are good, which can effectively prevent high-temperature vulcanization from returning to its origin.

(1) 2 parts of sulfur, 0.5 parts of accelerator M, 1 part of accelerator TMTD: the vulcanization speed of butyl reclaimed rubber is appropriate, the processing is safe, and the comprehensive performance of vulcanized rubber is poor.

(2) 1 part of accelerator DM, 1.5 parts of accelerator TDEDC: butyl reclaimed rubber has fast vulcanization speed, has a tendency to scorch some rubber materials, has good physical properties of vulcanized rubber, and has good anti-sulfur reversion.

(3) 2 parts of accelerator DTDM, 2 parts of TMTD: butyl reclaimed rubber has slow vulcanization speed, safe processing, good compression resistance and heat resistance.

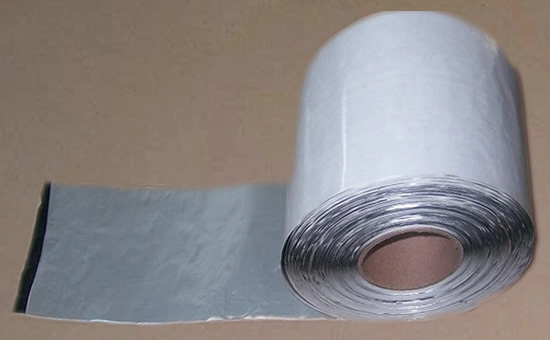

Butyl reclaimed rubber produces tire inner tubes, waterproofing membranes, container linings and most rubber products, and sulfur vulcanization systems are commonly used.

2. Butyl reclaimed rubber resin vulcanization system and vulcanized rubber characteristics

Butyl reclaimed rubber will form a stable -C-C- and -C-O-C- cross-linked bond during the vulcanization process when using resin vulcanization, in addition to thermal decomposition, the butyl reclaimed rubber with resin vulcanization will basically not occur vulcanization and return to the original phenomenon, and the vulcanized rubber has excellent heat resistance, high temperature resistance and low compression set performance. The commonly used resin vulcanizing agents for butyl reclaimed rubber include octylphenolic resin, tert-butyl phenolic resin, brominated hydroxymethyl phenolic resin, etc.

Compared with the sulfur-accelerator system, the amount of compounding agent in the vulcanization system of butyl reclaimed rubber resin is large and the vulcanization speed is slow, for example: 10 parts of alkyl phenolic resin, 5 parts of zinc oxide, 12 parts of bromide hydrocarbon cresol resin, 4 parts of stannous chloride; The butyl reclaimed rubber vulcanized with this vulcanization2SLYY1024 system has excellent aging resistance, as well as resistance to superheated steam and compression set. Butyl reclaimed rubber and butyl rubber are used together to produce vulcanized capsules, water tires, and tool glue, and are commonly used in resin vulcanization systems.

3. Characteristics of butyl reclaimed rubber quinone oxime vulcanization system and vulcanized rubber

The commonly used vulcanizing agents in the butyl reclaimed gum quinone oxime vulcanization system are p-quinone oxime and dibenzoyl p-quinone dixime, and the vulcanized rubber has good heat resistance, and the common combinations are as follows.

(1) 2 parts of p-quinone dixime, 6 parts of leaddan: butyl reclaimed rubber vulcanized rubber has poor aging resistance and good physical properties.

(2) 1.5 parts of p-quinone dixime, 4 parts of accelerator DM, 5 parts of lead oxide: butyl reclaimed rubber has fast vulcanization speed, easy scorching, good aging resistance and good electrical properties of vulcanized rubber.

(3) 1 part of p-quinone dixime, 3 parts of dibenzoyl-p-quinone dixime: butyl reclaimed rubber vulcanized rubber has good physical properties and is easy to burn.

(4) 3 parts of dibenzoyl-p-quinone dixime, 5 parts of lead: butyl reclaimed rubber vulcanized rubber has good comprehensive properties.

When using butyl reclaimed rubber to produce continuous vulcanized cables, sealants and other products, you can choose the vulcanization system of quinone oxime vulcanization system.

When using butyl reclaimed rubber as the main raw material to produce rubber products, rubber products manufacturers need to choose the appropriate vulcanization system according to the actual needs of the products, and if necessary, the two vulcanizing agents can be used together, with different accelerators and active agents.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits