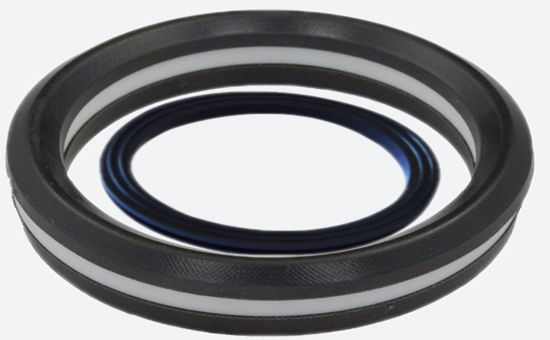

"What rubber oil resistance is good?" "Butadiene rubber and neoprene are good." "What rubber can be used to produce oil seals?" "Nitrile rubber!" The above dialogue can be said to be the common sense of rubber products industry. . However, in actual production, although the oil-resistant seal produced by nitrile rubber can maintain good sealing performance in oil environment for a long time, due to the high price of nitrile rubber itself, the production cost of nitrile rubber seal ring is high. At this time, the use of nitrile reclaimed rubber instead of nitrile rubber has become the best choice for rubber manufacturers to reduce costs.

Nitrile reclaimed rubber / raw rubber production oil seals formula: nitrile rubber, 100 parts; nitrile reclaimed rubber, 60 parts; zinc oxide, 5 parts; stearic acid, 2.5 parts; sulfur, 2 parts; accelerator DM, 1.5 parts; accelerator TMTD, 0.5 parts; antioxidant, 2.5 parts; plasticizer, 10 parts; white carbon black, 40 parts; glycerin, 3 parts; total: 227 parts.

The above formula can be used to produce oil seals with higher tensile strength.

In practical production, the use of nitrile reclaimed rubber and nitrile butadiene rubber can reduce the cost of raw materials, and can also ensure that various performance indicators of the oil seal ring meet the relevant standards; the oil resistance, tensile strength, etc. of the oil seal ring will follow As the amount of nitrile reclaimed rubber increases, it slowly decreases. Therefore, the amount of nitrile regenerated rubber added should not be too much; rubber manufacturers can use this as a basis to find a balance between the cost and quality of a nitrile reclaimed rubber.

When using nitrile reclaimed rubber/raw rubber to produce oil-resistant sealing rings, reasonable mixing of various compounding agents can improve the processing performance and performance of the nitrile oil-resistant oil seals: Accelerator DM and Accelerator TMTD Combining cure system Good, when there is more accelerator DM, a small amount of TMTD can adjust the vulcanization speed and prolong the scorch time; Anti-aging agent can delay the aging time of the oil-resistant sealing ring, prolong the service life, and can prevent aging in the formula of nitrile regenerated rubber/raw rubber oil seal ring Agent RD and anti-aging agent 4010NA are used in combination, in which RD has a significant protection effect against aging caused by hot oxygen. Anti-aging agent 4010NA has good dispersibility in nitrile rubber compound and will not affect the curing process; plasticizing in the formulation of Nitrile oil resistant seals DBP can be selected to improve the flexibility, stability, adhesion and flex resistance of nitrile regenerated rubber/raw rubber.

The price of nitrile reclaimed rubber is lower than that of nitrile rubber. Its performance is basically the same as that of nitrile rubber. The combination of nitrile reclaimed rubber and nitrile butadiene rubber has become the most commonly used production method for many nitrile rubber product manufacturers, which can guarantee nitrile rubber. Product quality can also reduce production costs. Hebei Hongyun Reclaimed Rubber Factory produces environmental-friendly nitrile reclaimed rubber with up to 90% of plastic content. It can directly replace N41, 35LM, Russia 26, Lanhua 26 and other nitrile rubbers to produce high-standard rubber products, significantly reducing raw material costs.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits