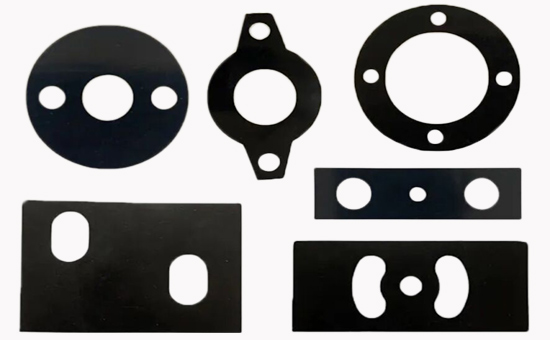

Rubber gasket is a kind of sealing element used in the connection of pipes, valves, pumps and other equipment, mainly used to prevent fluid or gas leakage; Nitrile gaskets have excellent oil resistance, good abrasion and tear resistance, and are extremely resistant to most fuels, greases, and lubricants, with maximum operating temperatures of 250 degrees Fahrenheit (121 degrees Celsius). Nitrile reclaimed rubber retains the basic performance characteristics of nitrile rubber, and can be used together with nitrile rubber to prepare heat-resistant rubber gaskets, effectively reducing the cost of raw materials.

1. Nitrile rubber/nitrile reclaimed rubber is used to produce heat-resistant rubber gaskets

(1) 50 parts of nitrile rubber, 50 parts of nitrile reclaimed rubber, 1.8 parts of zinc oxide, 0.4 parts of stearic acid, 1.8 parts of antioxidant 4010NA, 70 parts of carbon black N550, 2 parts of liquid polybutadiene, 0.8 parts of accelerator TETD, 0.8 parts of accelerator TMTD, 2.8 parts of accelerator TMTM, 2 parts of vulcanizing agent DTDM; Total: 182.4 parts.

(2) 70 parts of nitrile rubber, 30 parts of nitrile reclaimed rubber, 4.5 parts of zinc oxide, 1 part of stearic acid, 2.2 parts of antioxidant RD, 78 parts of carbon black N774, 5 parts of triphenyl phosphate, 1 part of accelerator CZ, 2 parts of accelerator TMTD, 0.3 parts of sulfur, total: 194 parts.

2. Key points in the design of formula to improve the heat resistance of nitrile rubber/reclaimed rubber gasket

(1) Vulcanization system: When using nitrile rubber and nitrile reclaimed rubber together to produce heat-resistant rubber gaskets, choose peroxide vulcanization system, effective vulcanization system, and semi-effective sulfur vulcanization system, and the heat resistance of vulcanized rubber is better than that of ordinary sulfur vulcanization.

(2) Protection system: choose high-efficiency heat-resistant antioxidants, such as antioxidant RD, and can be used in combination with other antioxidants such as MB, MBZ, 4010NA or 4020 to effectively improve the heat resistance of nitrile rubber/reclaimed rubber vulcanized rubber.

(3) Softening system: plasticizers should be used as little as possible in heat-resistant formulations, and plasticizers with relatively better high temperature resistance should be selected, such as polyester plasticizers with high boiling point and low volatility, trimethylphenyl phosphate 2SLYY117, trioctyl trimelliphthalate, etc., to avoid the migration or volatilization of plasticizers at high temperatures, resulting in the degradation of the performance of heat-resistant rubber gaskets of nitrile reclaimed rubber.

(4) Reinforcing filling system: carbon black is a commonly used reinforcing agent for nitrile rubber heat-resistant gaskets, and it is more beneficial to choose fast-pressing furnace black and semi-reinforcing carbon black to improve the heat resistance of rubber compounds.

When mixing reclaimed rubber in heat-resistant nitrile rubber gaskets, rubber products factories must choose suitable nitrile reclaimed rubber products according to actual needs, and will continue to discuss related issues with you in the future.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits