When using EPDM recycled rubber, EPDM rubber/recycled rubber, and using rubber to produce rubber products, a reasonable design of the softening and plasticizing system can not only improve the processing performance of the rubber material, including mixing, extrusion, rolling, and mold filling fluidity, but also further reduce costs. The commonly used softeners for EPDM rubber include paraffin oil, aromatic oil, naphthenic oil, mechanical oil, ointment, as well as petroleum resin, asphalt, pine tar, coumarone, etc; Different types of EPDM recycled rubber products have different performance requirements and need to be combined with different softeners and plasticizers.

1. Combination of the softening agent and vulcanizing agent for EPDM recycled rubber softening system

When sulfur vulcanization is used for rubber products using EPDM recycled rubber as the main raw material, the type and amount of mineral operating oil have little effect on the vulcanization of the rubber compound.

When ethylene propylene diene monomer (EPDM) recycled rubber is crosslinked with peroxide, the active free radicals used for crosslinking undergo a competitive hydrogen extraction reaction with the operating oil, which consumes them. The higher the aromatic content, the more active the hydrogen atoms are, and the greater the hydrogen extraction tendency, which has a greater impact on peroxide vulcanization. The greater the UV absorption of paraffin oil at 260nm (the wavelength of the aromatic structure absorption peak), the lower the degree of vulcanization of peroxide vulcanized rubber.

Therefore, it is recommended to use paraffin oil in the recycled EPDM rubber compound vulcanized with peroxide to avoid the use of aromatic operating oils; The greater the amount of human operated oil added to the rubber material, the greater the impact on vulcanization, and the degree of vulcanization of the rubber material is greater than when there is no or less oil added Low degree; When using paraffin oil as a softener, the amount of paraffin oil should not exceed 30 parts.

2. The dosage of the softening system for EPDM recycled rubber needs to be determined based on the performance indicators of the rubber material and the requirements of the processing technology

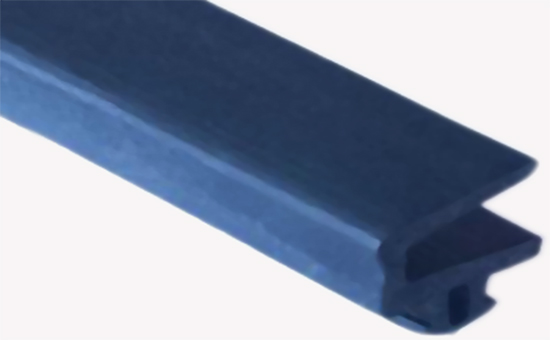

When using EPDM recycled rubber, EPDM rubber/recycled rubber, and using rubber to produce rubber sealing strips, the amount of softener should be determined based on the performance indicators of the rubber material and the required processing performance. As the amount of softener increases, the rubber content of the rubber compound decreases, the resilience and physical and mechanical properties of the vulcanizate decrease, and the compression set increases. When producing EPDM recycled rubber products that require low compression permanent deformation or good physical and mechanical properties, the amount of softener should be controlled among 5-30 parts.

When using EPDM recycled rubber to produce rubber sealing strips, heat-resistant conveyor belts, and other rubber products formed by extrusion or rolling, it is required that the rubber material has good plasticity. To ensure smooth processing and stable product size, the rubber content 2SLYY425 should not be too high, and the amount of softener can be appropriately increased, controlled among 40-100 parts; When using high Mooney viscosity EPDM raw rubber in EPDM recycled rubber products, the amount of softener can be appropriately increased.

In actual production, the softener itself has a significant impact on the physical and mechanical properties and processing performance of EPDM recycled rubber, such as the influence of paraffin hydrocarbon operating oil on the viscosity, scorching property, crosslinking speed, and tensile strength, elongation at break, hardness, and elasticity of EPDM recycled rubber; In EPDM rubber, for every 2 parts increase in 300 # paraffin oil, the hardness of the rubber decreases by approximately 1 degree.

It should be noted that due to the large amount of softener used in EPDM recycled rubber products, it is recommended to preheat the softener or increase the mixing temperature to ensure rapid mixing of the softener during mixing. In the future, the editor will continue to share with you the tips for adding commonly used softeners to EPDM recycled rubber products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits