Compared with other kinds of recycled rubber, EPDM recycled rubber has better resistance to high temperature, ozone and sunlight aging, and can be used in the production of rubber products with high requirements for aging resistance. When using EPDM recycled rubber to produce rubber products, the rubber product manufacturer needs to select the appropriate type of antioxidant according to the protection focus of the products, among which amine antioxidant and phenolic antioxidant are more used in EPDM recycled rubber products.

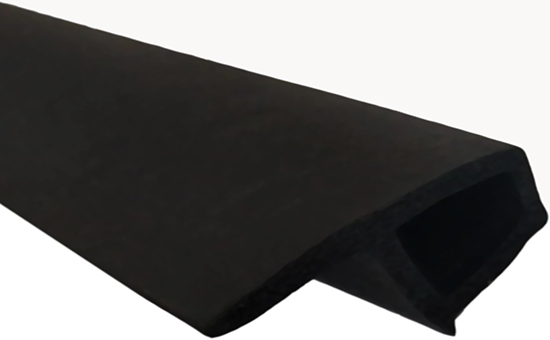

EPDM recycled rubber can be used alone or in combination with EPDM raw rubber to produce automobile sealing strips, building door and window sealing strips, tires, rubber tubes, wires and cables, and waterproof rolls; Different rubber products in different applications have different requirements for aging resistance, and a reasonable aging prevention system for EPDM recycled rubber products is required.

When EPDM recycled rubber is used to produce rubber products without special requirements for heat aging and other special properties, anti-aging agent may not be used. In actual production, the heat aging performance of EPDM reclaimed rubber vulcanizate is better when the effective curing system with low sulfur content and peroxide curing system are used for curing.

The use of EPDM recycled rubber to produce rubber products with high requirements for heat resistance, such as automotive radiator rubber hose, needs to be matched with heat resistant antioxidant, commonly used free radical catchers, such as antioxidant RD, BLE, 264, etc; When antioxidant RD and other antioxidants MB and MTI are used together, the heat aging performance of vulcanizates is better, and the combination system of antioxidant RD and MB is the most widely used. In the anti-aging system of EPDM reclaimed rubber, the proportion of antioxidant is generally among 2-4 parts.

Curing system should also be considered when designing the anti-aging system of EPDM recycled rubber products. When selecting peroxide vulcanization for EPDM recycled rubber products, it is necessary to pay attention to the possible influence of free radical catcher 2SLYY31 on vulcanization in the design of anti-aging system, which generally has a greater impact on phenylenediamines and a smaller impact on polymerized quinolines; Therefore, quinoline antioxidant (RD, 4010NA, 4020, etc.) is recommended to be used in the peroxide vulcanizate of EPDM reclaimed rubber.

When EPDM recycled rubber products require that the rubber material does not migrate or change color, it is recommended to use non-polluting phenolic antioxidant, such as antioxidant 2246. Antioxidant 2246 has better inhibition on thermal oxygen, weather aging, flex aging and variable metal than antioxidant 264, and its protective effect is close to that of amine antioxidant A and antioxidant Ding.

What other issues should be paid attention to when designing the anti-aging system of EPDM recycled rubber products? The editor looks forward to discussing with you.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits