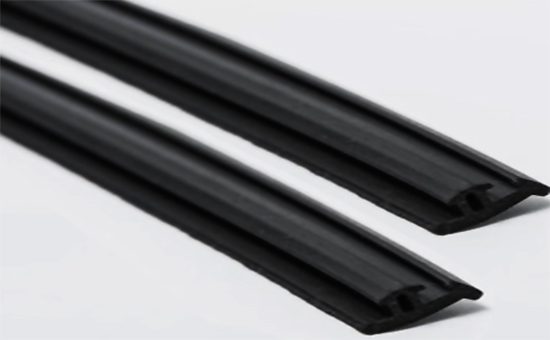

EPDM recycled rubber has excellent heat resistance, weather resistance, aging resistance, etc., and is widely used in construction, automobiles, cables, wires, hose tapes, and other industries. Good aging resistance is one of the advantages of EPDM reclaimed rubber, which can maintain good performance after long-term use. When using EPDM reclaimed rubber as the main raw material to produce rubber products, do I need to add antioxidants? What are the commonly used antioxidants in EPDM reclaimed rubber products? What are the characteristics?

1. Do EPDM recycled rubber products need to add antioxidants?

Whether antioxidants need to be added in the production of EPDM recycled rubber products, it is necessary to determine the performance E4LYY329 requirements of reclaimed rubber products and rubber products, if rubber products need to be used outdoors or exposed to ultraviolet rays, ozone and other harsh environments, adding antioxidants can improve the weather resistance and aging resistance of the product. If EPDM reclaimed rubber has been added enough antioxidant in the production process, or its stability is good, additional antioxidant may not be needed.

The addition of antioxidants also increases production costs, so it is necessary to weigh the costs and benefits and decide whether to add antioxidants based on the expected life and performance requirements of the product. Small-scale trials are recommended to evaluate the impact of added antioxidants on product performance to determine the optimal formulation and production process to better balance quality and cost.

2. EPDM recycled rubber commonly used antioxidants and their characteristics

(1) Free radical inhibitors

Free radical inhibitors, also known as scavengers, such as amines, phenols, and hydroquinolins, inhibit the chain reaction of free radicals by providing hydrogen atoms that are more reactive than rubber molecules, avoiding the hydrogen capture reaction of macromolecules. This type of antioxidant has a significant effect on preventing the oxidative aging of EPDM recycled rubber.

(2) Peroxide decomposition agent

Peroxide decomposers, or anti-aging synergists, such as organosulfurs (antioxidants MB, MTI, etc.) and organophosphorus compounds, can prevent the continuous regeneration of active groups. These antioxidants help to reduce the aging of EPDM recycled rubber due to peroxides during processing.

(3) Ultraviolet light stabilizer

UV light stabilizers, such as benzotriazoles, organonickels, and hindered amines, can prevent chain initiation caused by UV light, thereby protecting rubber from UV damage. This is particularly important to improve the durability of EPDM recycled rubber products in outdoor environments.

(4) Harmful metal inhibitors

Harmful metal inhibitors, such as amines, phenols, organosulfurs, and organophosphorus compounds, can mitigate the catalytic effects of harmful metals on aging. This type of antioxidant helps to prevent the destruction of the rubber molecular chain by metal ions and prolongs the service life of EPDM recycled rubber.

In actual production, amines and phenolic antioxidants are the most widely used. The protective effect of general amines is much stronger than that of phenols, but its pollution is correspondingly large, especially the pollution and migration of p-phenylenediamine antioxidants are the strongest, and they should be avoided in light-colored products. When using EPDM recycled rubber to produce rubber products, different varieties of rubber products may have different requirements for rubber compounds in terms of heat resistance, ozone resistance, flexural crack resistance, light aging resistance, etc., so it is recommended to comprehensively consider the protective characteristics and mechanism of various antioxidants, as well as the synergistic effects among them, to determine the appropriate type and dosage of antioxidants.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits