Calendering is a common molding method in the production of rubber products. Recycled rubber is the third largest rubber type after natural rubber and synthetic rubber. The products are also calendered. The performance of different types of reclaimed rubber is different. Among them, latex reclaimed rubber is the best product of calendering process. Calendering is also one of the most commonly used molding methods for latex reclaimed rubber products; then what are the factors related to the calendering process performance of reclaimed rubber, and how to further improve latex reclaimed rubber rolling What about the operation process?

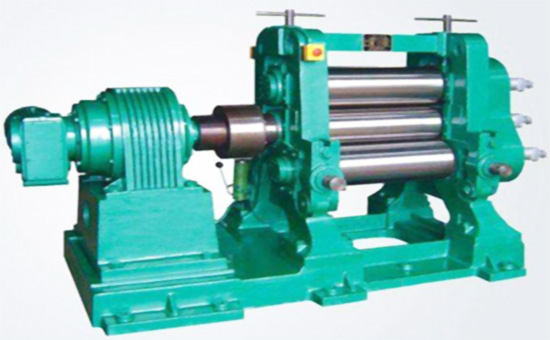

Calendering is a processing method in which a viscous compound is pressed and stretched several times at a specific processing temperature by means of a strong shear force between rolls, and finally becomes a sheet product having a certain width and thickness; reclaimed rubber rolling The process operation is directly related to the rubber content, Mooney viscosity, elasticity, plasticity, expansion ratio and shrinkage rate of the rubber compound. Generally, the higher the rubber content, the greater the elastic deformation, the higher the Mooney viscosity and the lower the plasticity. The worse the fluidity and the greater the expansion ratio shrinkage rate, the more difficult the reclaimed rubber calendering process is. On the contrary, the higher the tensile strength of the reclaimed rubber and the higher the calcining efficiency of the reclaimed rubber, the rubber product manufacturer can replace the reclaimed rubber and adjust the reclaimed rubber. Product formulation to improve the calendering process of reclaimed rubber products.

Latex reclaimed rubber is processed from waste natural rubber and waste latex products. It retains the basic structural characteristics of natural rubber, high molecular chain, wide molecular mass distribution, easy molecular chain breakage, easy calendering process, and unique internal molecular structure. It imparts good calendering performance to latex reclaimed rubber and is an ideal raw material for calendered products.

Rubber products manufacturers use latex reclaimed rubber to produce rubber products. When rolling process is adopted, the process performance of latex reclaimed rubber can be further improved by reasonable formula design according to the factors affecting the process of reclaimed rubber rolling process:

1 Reduce the amount of gelatin in the formula. Generally, the higher the rubber content, the better the overall performance of the rubber product produced by the latex reclaimed rubber, but the higher the rubber content, the slower the calcining speed of the latex reclaimed rubber, and the lower the rubber content of the latex reclaimed rubber compound. Good, calendering speed is faster; therefore, rubber manufacturers choose latex reclaimed rubber and design formula to reduce the amount of formula in the formula to meet the performance requirements, such as the choice of low-capacity latex reclaimed rubber or filler.

2 Reasonably choose the type of compounding agent. The high activity soft carbon black, thermal cracking carbon black, calcium carbonate, clay and other fillers can improve the calendering process of latex reclaimed rubber to a certain extent. The active fillers such as talc powder and graphite can improve the rolling effect of the rubber compound. To improve the surface smoothness and dimensional stability of the calendered product; adding appropriate amount of softener such as coumarone, asphalt, ointment and process oil to the latex reclaimed rubber product formulation can reduce the shrinkage rate of the rubber compound, improve the plasticity and improve the rubber rolling The process; in addition, the use of an appropriate amount of scorch retarder, to avoid the moisture in the formulation of the formulation can improve the latex reclaimed rubber rolling effect.

The latex reclaimed rubber calendering process directly affects the surface quality and performance of the rubber products. The manufacturer needs to carry out reasonable rubber selection and formulation design. In the continuous improvement process of the rubber product process, there are more processes to improve the latex reclaimed rubber calendering process. The method is waiting for us to discover.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits