The tire rubber powder is the most important disposal method for waste rubber tires after the tire reclaimed rubber. The waste tire rubber powder processed from the waste tires can be used as a filler material or as a main material for the production of rubber products. There are several ways to use tire rubber powder in rubber tiles. Let's take a look at its usage and role.

Compared with hard floor and traditional floor tiles, rubber floor tiles have better elasticity and higher comfort, and can play a role of anti-slip and shock absorption. Therefore, they are widely used in ground paving projects in sports venues and event venues. In the production of various rubber floor tiles, tire rubber powder plays an important role, and it is of great significance to improve the performance of rubber floor tiles and reduce the production cost of floor tiles.

1, reclaimed rubber + tire rubber powder production of rubber tiles. At present, the main raw material for rubber floor tiles is reclaimed rubber, which can be produced through high-temperature vulcanization and used for rubber floor tiles. Generally, tire reclaimed rubber is used. When reclaimed rubber is used to produce rubber tiles, it is usually added with an appropriate amount of tire rubber powder. The production technology of waste tire rubber powder is simpler than that of tire reclaimed rubber, and the price is low. It can be used as a filler material to reduce the cost of rubber materials and improve the abrasion resistance and low temperature flexibility of rubber tiles.

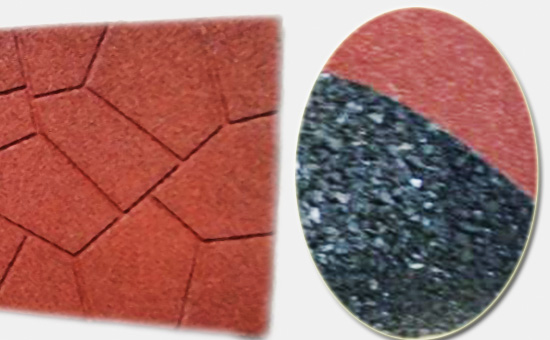

2, different fineness of rubber powder production of rubber tiles. In addition to rubber tiles produced from reclaimed rubber as the main material, there are many rubber tiles that are pressed directly using different fineness tire rubber powders. Under normal circumstances, the surface of such rubber floor tiles will be selected with high fineness tire rubber powder, and the bottom layer will be produced with crude tire rubber powder or tire particles. This type of rubber floor tile can be colored by selecting a suitable coloring process to produce beautiful rubber floor tiles of various colors.

3, tire rubber powder used alone to produce rubber tiles. The tire rubber powder itself can also be used as the subject material in the production of rubber floor tiles. 100 parts of tire rubber powder can be directly mixed, shaped and produced with 2-3 parts of sulfur, 1 part of accelerator and other processing aids. The process is simple, and the rubber floor tiles produced have good cushioning properties, slip resistance, water permeability, and certain insulation effects. Such rubber floor tiles are more suitable for livestock husbandry.

4, tire rubber powder + sawdust production of wood rubber tiles. Some foreign manufacturers press tire rubber powder together with sawdust and press them in a woody rubber floor tile. Compared with the above-mentioned floor tiles, the wooden rubber floor tile has not only the elasticity, wear-resistance and comfort of common rubber floor tiles, but also the performance of wooden materials, water permeability, Non-slip, generally 100 parts tire rubber powder with 20 pieces of dry sawdust. The low price of tire rubber powder and sawdust, and the low cost and good performance of rubber floor tiles produced are very popular in the market.

In fact, tire rubber powder can also produce shock-absorbing rubber plates, rubber gaskets, etc., which can significantly reduce the cost of raw materials.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits