Vulcanized rubber powder is a powdery rubber material obtained by crushing and processing waste rubber products. It can be directly added to various rubber products to improve the technological performance of the products and reduce the cost of raw materials. The rubber tube is a tubular rubber product processed from rubber as the main raw material for conveying various solids, liquids and gases. Adding an appropriate amount of vulcanized rubber powder can effectively reduce the production cost. So which hose production can add vulcanized rubber powder? The editor will share with you a few practical formulas for rubber tubes mixed with vulcanized rubber powder today.

1. The practical formula for adding vulcanized rubber powder to the water hose

100 parts of natural rubber, 160 parts of reclaimed rubber, 100 parts of vulcanized rubber powder, 10 parts of zinc oxide, 4 parts of stearic acid, 2 parts of antioxidant D, 2 parts of paraffin, 200 parts of light calcium, 10 parts of petroleum asphalt, 15 parts of engine oil, 1.7 parts of accelerator DM, 6.5 parts of sulfur, total: 611.2 parts.

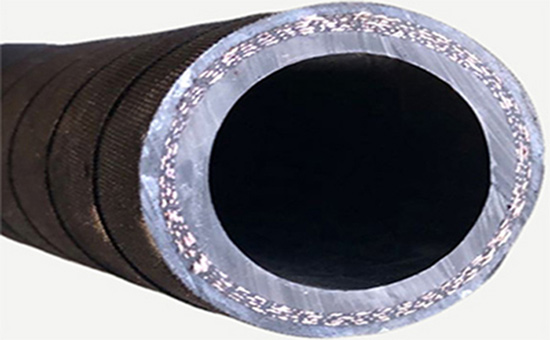

2. Practical formula for adding vulcanized rubber powder to the buried suction hose

(1) Middle rubber formula: 100 parts of natural rubber, 250 parts of reclaimed rubber, 200 parts of vulcanized rubber powder, 12 parts of zinc oxide, 2.5 parts of stearic acid, 1.5 parts of antioxidant D, 40 parts of carbon black, 15 parts of engine oil, 2 parts of accelerator M, 1.2 parts of accelerator DM, 9.2 parts of sulfur; Total 633.4 copies.

(2) Inner rubber formula: 100 parts of natural rubber, 220 parts of reclaimed rubber, 90 parts of vulcanized rubber powder, 5 parts of zinc oxide, 2.5 parts of stearic acid, 1.5 parts of antioxidant, 40 parts of carbon black, 85 parts of light calcium, 18 parts of engine oil, 1.3 parts of accelerator M, 1.2 parts of accelerator DM, 4.2 parts of sulfur; Total: 568.7 shares.

3. Practical formula for adding vulcanized rubber powder to sandblasting hose

Inner rubber formula: 50 parts of natural rubber, 50 parts of butadiene rubber, 20 parts of vulcanized rubber powder, 3 parts of zinc oxide, 2.5 parts of stearic acid, 3 parts of antioxidant, 60 parts of carbon black, 6 parts of pine tar, 10 parts of coumarone, 5 parts of engine oil, 1.6 parts of accelerator, 3 parts of sulfur; Total: 214.1 shares.

Hose with vulcanized rubber powder to reduce cost generally uses sulfur vulcanization, carbon black reinforcement, calcium carbonate filling, using engine oil, pine tar, etc. as softeners, and using antioxidant D to delay product aging. When using vulcanized rubber powder 2ELYY527 to reduce the production cost of rubber tubes, the higher the fineness of the rubber powder, the better the addition effect among the rubber layers of the rubber tube. In actual production, the addition of vulcanized rubber powder can also reduce the generation of bubbles in the extrusion of the hose, and improve the tear resistance and flexural fatigue resistance of the finished product; the editor will continue to discuss related issues with you in the follow-up.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits