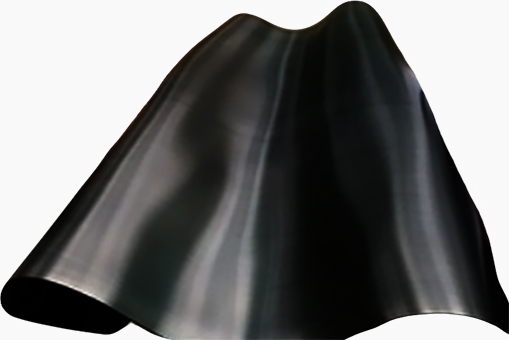

Rubber sheets are processed with rubber as the main raw material. According to the performance, they can be divided into ordinary rubber sheets, acid and alkali resistant rubber sheets, heat-resistant rubber sheets, oil-resistant rubber sheets, flame-retardant rubber sheets, insulating rubber sheets, conductive rubber sheets, and rubber sheets. Grinding rubber sheets, etc., different types of rubber sheets use different rubber raw materials. Vulcanized rubber powder processed from waste rubber products by machinery, freezing and crushing can be reasonably added to the production of rubber sheets to improve the flexural resistance and tear resistance of rubber sheets while reducing costs.

1. Skills of using vulcanized rubber powder for ordinary industrial rubber sheets

Ordinary industrial rubber sheets are processed with natural rubber, styrene-butadiene rubber, cis-butadiene rubber, and recycled rubber as the main raw materials, or rubber and plastic are used together, and the rubber content is generally controlled 20%-40%.

In actual production, it is recommended to use 60-80 mesh tire rubber powder in ordinary industrial rubber sheets, and the dosage is among 50-200 parts. For ordinary industrial rubber sheets mixed with vulcanized rubber powder 2ELYY621 (mostly tire rubber powder), it is recommended to use sulfur vulcanization, accelerator M or accelerator DM and accelerator D are used together, and a small amount of TMTD can be added if necessary; carbon can be used in the reinforcement filling system Black, calcium carbonate, clay; use engine oil or coumarone to form a softening system to improve the processing performance of the rubber compound.

2. Tips for using vulcanized rubber powder for acid and alkali resistant rubber sheets

The acid and alkali resistance of the rubber itself directly determines the acid and alkali resistance of the rubber sheet. Generally, diene rubber can be used to produce ordinary acid and alkali resistant rubber sheets. Most of the rubber sheets used under high concentration conditions use butyl rubber and silicone rubber. , fluorine rubber, etc.

When natural rubber is used as the main raw material to produce ordinary acid and alkali resistant rubber sheet, 10-20 parts of tire rubber powder can be added to reduce the cost on the premise of ensuring the acid and alkali resistance of the rubber sheet. In actual production, it is recommended to use sulfur vulcanization for acid and alkali-resistant rubber sheets mixed with vulcanized rubber powder, filling with chemically inert fillers such as clay, barium sulfate, talc, diatomaceous earth, etc., and choose softeners that do not interact with acid and alkali. , Plasticizers improve the processing properties of rubber compounds.

3. Tips for using vulcanized rubber powder for anti-static rubber sheets

Anti-static rubber sheets are insulating rubber sheets and anti-static rubber pads, which have low requirements on mechanical strength and are generally processed from nitrile rubber as the main raw material. In actual production, adding an appropriate amount of vulcanized rubber powder to the antistatic rubber sheet can achieve the multiple purposes of shortening the vulcanization time, improving the vulcanization efficiency and reducing the cost of raw materials. When adding vulcanized rubber powder to the anti-static rubber sheet, try to choose high-fineness rubber powder, such as 80-120 mesh vulcanized rubber powder; appropriately reduce the amount of vulcanizing agent and accelerator in the formula, or use after-effect accelerator; or Use a scorch retarder.

4. Industrial rubber sheet, acid and alkali resistant rubber sheet mixed with tire rubber powder formula

(1) Reference formula for general industrial rubber sheet mixed with tire rubber powder: 40 parts of natural rubber, 60 parts of oil-extended styrene-butadiene rubber, 120 parts of tire rubber powder, 4 parts of zinc oxide, 2.2 parts of stearic acid, 1 part of antioxidant A , 1 part of antioxidant D, 2 parts of paraffin, 30 parts of carbon black N330, 110 parts of heavy calcium, 7 parts of motor oil, 7 parts of pine tar, 0.8 parts of accelerator DM, 1.25 parts of accelerator M, 0.15 parts of accelerator TMTD, sulfur 2.6 copies; total: 389 copies.

(2) Reference formula of tire rubber powder mixed with acid and alkali resistant rubber sheet: 100 parts of natural rubber, 5 parts of zinc oxide, 1 part of stearic acid, 3 parts of anti-aging agent, 10 parts of carbon black, 30 parts of clay, 60 parts of barium sulfate powder parts, 30 parts of talcum powder, 10 parts of tire rubber powder, 1.5 parts of accelerator, 2.5 parts of sulfur; total: 253 parts.

In actual production, flame-retardant rubber sheets, oil-resistant rubber sheets, conductive rubber sheets and other types of rubber sheets can also be added with a certain proportion of vulcanized rubber powder. Later, the editor will continue to discuss related issues with you.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits