Pressure-sensitive adhesives are very sensitive to pressure. High-quality pressure-sensitive adhesives have good adhesion, wettability, temperature resistance, flame retardancy, corrosion resistance, aging resistance and other properties. Butyl rubber has excellent air tightness, water tightness, good chemical stability and thermal stability. It is a commonly used synthetic rubber for preparing pressure-sensitive adhesives. At present, many pressure-sensitive adhesives with butyl rubber as the main material are used in waterproof materials such as waterproof rolls. Rubber manufacturers want to use appropriate amount of recycled adhesives in butyl pressure-sensitive adhesives to reduce costs. Is it feasible to use 1JLY910?

1. Can Butyl Recycled Adhesive be Used in Butyl Pressure Sensitive Adhesive

Compared with butyl rubber, the mechanical strength of reclaimed butyl rubber is low, but its heat resistance, aging resistance and air permeability are inherited. It has high cohesion strength, good elasticity, high vulcanization activity and good compatibility with butyl rubber. In theory, it can be added to the preparation of butyl pressure sensitive rubber materials to reduce the cost of pressure sensitive collagen materials.

2. Which Butyl Recycled Adhesives Can Be Used in Butyl Pressure Sensitive Adhesives

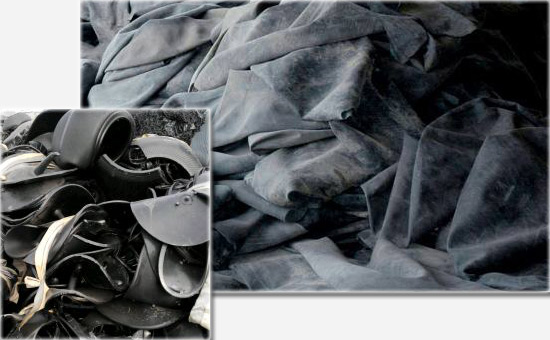

At present, the commercially available reclaimed butyl rubber mainly includes reclaimed butyl rubber made from waste butyl inner tube, reclaimed butyl rubber made from waste butyl inner tube, reclaimed capsule rubber made from waste butyl vulcanized capsule and reclaimed chlorinated butyl rubber made from waste medical bottle cap and bottle stopper. The results showed that the butyl inner tube regenerated rubber, the butyl water tire regenerated rubber and the capsule regenerated rubber could be used in the preparation of the butyl pressure sensitive adhesive.

3. Amount of Butyl Recycled Adhesive in Butyl Pressure Sensitive Adhesive

When the butyl rubber is used as the main raw material in the pressure-sensitive adhesive, the rubber manufacturer can choose a single butyl-based reclaimed rubber and butyl rubber, or mix two kinds of butyl-based reclaimed rubber into the formula of the butyl pressure-sensitive adhesive. The manufacturer can reasonably control the butyl-based reclaimed rubber according to the actual demand and the index of the reclaimed rubber. The amount of glue is enough.

The results showed that the heat resistance and aging resistance of the pressure sensitive adhesive remained basically unchanged with the increase of the amount of the reclaimed butyl rubber used in the formulation of the butyl pressure sensitive adhesive, but because the molecular weight of the reclaimed butyl rubber itself was small and the molecular size was not regular, the more the amount of the reclaimed rubber used, the mechanical strength of the pressure sensitive adhesive, such as peeling strength, would be increased. The amount of reclaimed butyl rubber should be controlled reasonably. Taking butyl rubber/capsule reclaimed rubber/butyl water tire reclaimed rubber as an example, the comprehensive index of pressure sensitive adhesive prepared by controlling the dosage of the three compounds at 2:1:1 is better.

It can be seen that when the cost of pressure sensitive collagen material is reduced by using reclaimed butyl rubber, the dosage of reclaimed butyl rubber should be controlled at about 50%.

4. Category and dosage of butyl pressure-sensitive adhesives containing regenerated adhesives

When using reclaimed butyl rubber to reduce the production cost of butyl pressure sensitive adhesives, rational use of compounding agent can further improve the comprehensive index of pressure sensitive adhesives and reduce more production costs. Among them, when filling with calcium carbonate and tackifying with terpene resin, the dosage of calcium carbonate should be controlled between 180 and 200 phrases, and the dosage of terpene resin should be controlled between 60 and 80 phrases. A small amount of carbon black, white carbon black and appropriate amount of paraffin oil should be used in the production of pressure sensitive adhesive by using butyl rubber/recycled rubber.

When using butyl reclaimed rubber to reduce the cost of butyl pressure sensitive collagen, rubber manufacturers must reasonably select reclaimed rubber and formulation, determine the dosage of compound and formulation according to specific needs, and reduce more production costs on the premise of ensuring quality.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits