Butyl rubber has excellent air tightness, water tightness, heat resistance, chemical corrosion resistance, aging resistance, used in the production of rubber sealing strips, the finished product sealing effect is good, long service life. China's butyl rubber market has long been in short supply, butyl rubber prices are high, and many butyl rubber sealing strip manufacturers have set their sights on butyl reclaimed rubber. So can butyl reclaimed rubber produce rubber sealing strips? How to design the formulation of rubber sealing strips containing butyl reclaimed rubber?

1. Butyl rubber/butyl reclaimed rubber is used to produce a vulcanized formula for rubber sealing strips

(1) 70 parts of butyl rubber, 30 parts of butyl reclaimed rubber, 5 parts of zinc oxide, 1.5 parts of stearic acid, 5 parts of paraffin, 70 parts of carbon black N550, 10 parts of calcined clay, 18 parts of mineral oil, 2 parts of diethylene glycol, 1 part of accelerator DM, 2 parts of accelerator ZDC, 0.5 parts of sulfur, 1.5 parts of vulcanizing agent DTDM; total: 216.5 parts.

(2) 50 parts of butyl rubber, 50 parts of butyl reclaimed rubber, 4 parts of zinc oxide, 1.5 parts of stearic acid, 70 parts of carbon black N550, 3 parts of petroleum jelly, 28 parts of naphthenic oil, 0.5 parts of accelerator M, 1 part of accelerator TDEC, 0.8 parts of accelerator TMTD, 1.5 parts of sulfur; total: 210.3 copies.

In actual production, butyl reclaimed rubber can also completely replace butyl rubber to produce rubber sealing strips, effectively reducing the cost of raw materials.

2. Key points of formula design of butyl reclaimed rubber replacing butyl original rubber for the production of rubber sealing strips

(1) Considering the use environment and physical property requirements of butyl rubber sealing strips, select the butyl reclaimed rubber with appropriate indicators, and reasonably determine the mixing ratio of reclaimed rubber through experiments.

(2) In order to ensure the stability of the structure and size of the special-shaped rubber sealing strip in the production, an appropriate amount of supporting compounding agents can be added to the formula, such as ointment, polymer wax, modified plastics, etc., and the finished rubber strip has good stiffness and small deformation.

(3) Fully consider the performance of rubber extrusion process when designing the formula

The use of black and white ointment, mineral oil, clay, stearic acid and other compounding agents can improve the extrusion speed of butyl rubber/butyl reclaimed rubber and semi-finished rubber with rubber, and keep the semi-finished products smooth; The use of ointment and magnesium carbonate can reduce the deformation of the semi-finished product E4LYY415 the parking time. Appropriately increase the amount of softener and plasticizer in the formula, improve the plasticity of the rubber compound, increase the fluidity of the rubber compound, make the surface of the butyl rubber/reclaimed rubber semi-finished product smooth, reduce the scorch during extrusion, and improve the extrusion speed.

(4) When the butyl rubber sealing strip has high requirements for aging resistance, antioxidants and antioxidants can be used together, such as antioxidant 4010NA and antioxidant RD.

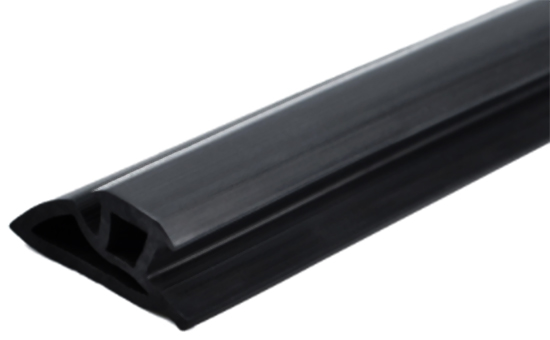

The use of butyl reclaimed rubber instead of part of the butyl rubber production of sealing strips can be used in building doors and windows, glass curtain walls, electronic equipment, household appliances, automobiles and other fields of sealing, different use occasions of butyl rubber sealing strip physical property requirements, not only need to reasonably design the vulcanization formula, but also need to properly adjust the production process, especially the mixing, vulcanization process, the follow-up Xiaobian will continue to share with you butyl rubber/butyl reclaimed rubber and use the production of rubber sealing strip production process points.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits