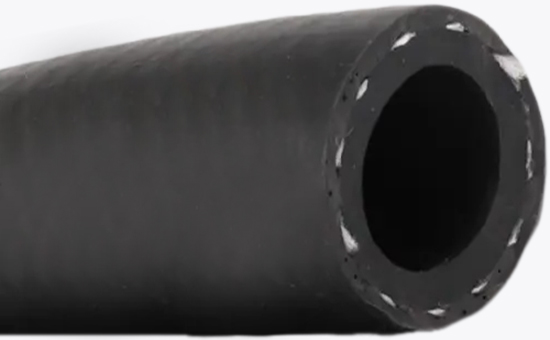

Nitrile reclaimed rubber is a waste nitrile rubber products processed by crushing, desulfurization, refining and other processes, retaining the basic performance characteristics of nitrile rubber, can be used in whole or in part to replace nitrile rubber and PVC resin, prepare high-performance rubber and plastic elastomers, widely used in the production of oil-resistant hoses, cables and other products, reasonable design of nitrile reclaimed rubber/PVC blend material formula, further improve the comprehensive performance and processing technology of finished products, and reduce the cost of raw materials.

1. Performance characteristics of nitrile reclaimed rubber/PVC resin blend material

Add an appropriate amount of polyvinyl chloride resin to nitrile reclaimed rubber or nitrile rubber/nitrile reclaimed rubber combined with rubber, the ozone resistance, weather resistance, oil resistance, solvent resistance and chemical resistance of the blend material are improved, the abrasion resistance and tear resistance are increased, the tensile strength, tensile strength and heat resistance are improved, the reciprocating flexion and cracking resistance is better, the extrusion performance is better, and the rubber material is not easy to self-vulcanization.

2. Nitrile reclaimed rubber/PVC resin blend material formula design

(1) Nitrile reclaimed rubber and PVC resin selection: when blending nitrile rubber and PVC to prepare high-performance elastomer materials, it is recommended to choose nitrile butadiene rubber with medium acrylonitrile content and nitrile reclaimed rubber, which is more compatible with PVC; When the proportion of polyvinyl chloride is high, it is recommended to choose polyvinyl chloride resin polymerized by emulsion.

(2) Nitrile reclaimed rubber/PVC blend material filling system

When nitrile rubber, nitrile reclaimed rubber and PVC are used together, hot cracking carbon black is commonly used for reinforcement, and calcium carbonate, silica and clay can be used for light-colored products. When the nitrile reclaimed rubber/PVC blend material is filled with calcium carbonate, dioctyl phthalate, trimethylbenzyl phosphate E4LYY1129, and liquid chlorinated biphenyl are used as plasticizers, and the filling effect is better, and there is no cracking or frosting on the surface. Choosing the right filler for nitrile reclaimed rubber/PVC blends can improve the process performance of the compound, such as reducing the shrinkage of semi-finished products, reducing the Mooney viscosity of the compound, and improving elasticity and low-temperature properties.

(3) Nitrile reclaimed rubber/PVC blend plasticization system: commonly used polar plasticizers, such as phthalates, adipates, sebacates, phosphates, etc.; The selection of plasticizers with high volatilization point, low freezing point and moderate molecular weight can improve the low-temperature performance of the rubber compound. The amount of plasticizer used depends on the amount of filler used, and too much amount is easy to migrate and spray, generally no more than 30 parts.

(4) Nitrile reclaimed rubber/PVC blend material antioxidant system: phenolic antioxidant is recommended; Amine antioxidants will promote the thermal decomposition of polyvinyl chloride and should not be used.

(5) Vulcanization system of nitrile reclaimed rubber/PVC blend material

When nitrile rubber, nitrile reclaimed rubber and polyvinyl chloride are blended, a sulfur-accelerator system can be used in the formula, and accelerator M and accelerator DM can be used with sulfur; The accelerator TMTD/DPG will promote the decomposition of polyvinyl chloride and should be avoided as much as possible. When zinc oxide is used as a vulcanizing active agent for nitrile reclaimed rubber/PVC blend (less than 5 parts are not affected), a sufficient amount of PVC stabilizer needs to be added; Magnesium oxide and lead oxide can also be used as sulfidation active agents, among which zinc oxide has a stabilizing effect on polyvinyl chloride.

It should be noted that the addition of polyvinyl chloride will lead to the deterioration of the compression deformation of nitrile rubber and nitrile reclaimed rubber, and it is necessary to obtain effective compensation by increasing the dosage of compounding agent in the vulcanization system.

In the nitrile rubber, nitrile reclaimed rubber, nitrile rubber/reclaimed rubber and rubber with an appropriate amount of polyvinyl chloride resin, reasonable design formula, blended rubber ozone resistance, weather resistance, oil resistance is better, in the oil-resistant hose, cable sheath, automotive seals, shock absorption gaskets and other products are widely used, improve the rubber processing technology, improve production efficiency, reduce production costs.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits