Nitrile rubber and nitrile reclaimed rubber have excellent oil resistance and good abrasion resistance, and can be used to produce various oil and wear resistant rubber products. In actual production, the sulfur/accelerator system is the most widely used vulcanization system for nitrile rubber, nitrile reclaimed rubber or nitrile rubber/reclaimed rubber. When nitrile rubber is vulcanized with sulfur, the appropriate accelerator should be selected according to the specific performance requirements of the rubber product, and the amount of sulfur and accelerator should be reasonably controlled to further optimize the overall performance of the nitrile rubber product.

1. Control the amount of sulfur

When nitrile rubber, nitrile reclaimed rubber or nitrile virgin rubber/reclaimed rubber are combined with sulfur vulcanization, use sulfur powder. Since the solubility of sulfur in nitrile rubber is lower than that of natural rubber, it is necessary to control the amount of sulfur reasonably. In actual production, in order to avoid blooming of nitrile rubber products, it is recommended to use insoluble sulfur.

In general, the amount of sulfur in the soft nitrile rubber is controlled at 1.5-2 parts, the usual amount of accelerator is 1-3.5 parts, and the amount of sulfur in the soft nitrile vulcanizate is preferably controlled at about 1.5 parts. When using different acrylonitrile content of nitrile rubber 2YLYY1029 or nitrile reclaimed rubber to produce rubber products, the higher the acrylonitrile content, the appropriate reduction of the amount of sulfur; for example, the amount of sulfur in nitrile-18 is mostly 1.75-2 parts, and nitrile-26 The amount of medium sulfur is recommended to be controlled among 1.5-1.75 parts.

2. Nitrile low-sulfur high-promoting coordination system

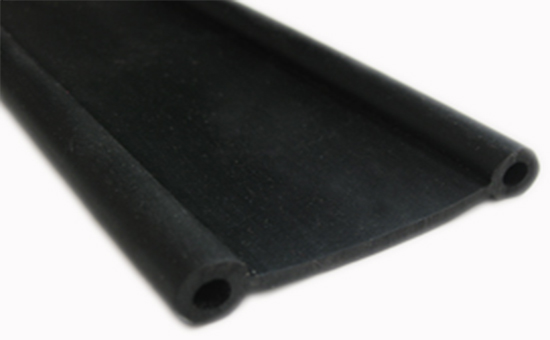

When using nitrile rubber or nitrile reclaimed rubber to produce rubber products that require high compression and permanent deformation resistance, such as oil seals, gaskets, etc., low-sulfur and high-vulcanization systems are often used, and the sulfur content is less than 0.5 parts, which can effectively increase The heat resistance of vulcanized rubber can reduce the compression permanent deformation of the rubber compound.

3. Commonly used accelerators for nitrile rubber

The commonly used accelerators for vulcanization of nitrile rubber or nitrile reclaimed rubber are thiuram accelerators and thiazole accelerators. The vulcanizates using thiuram accelerators have good overall performance, especially the compression set resistance. In addition, nitrile rubber compounds can also use sulfenamide accelerators, and amine accelerators and guanidine accelerators are often used as auxiliary accelerators.

4. Common sulfur-accelerator system coordination

When sulfur is combined with thiuram disulfide accelerators such as accelerators TMTD, TRA, and TRT, the nitrile vulcanizate has excellent heat resistance. When sulfur is used in combination with thiuram monosulfide, the nitrile vulcanizate has lower compression set and minimal scorch tendency. Choose high-volume thiurams and sulfenamides together or low-sulfur formula with thiurams and thiazoles. The nitrile vulcanizate has high mechanical strength, heat resistance, small compression set, and is not easy to scorch and bloom.

In addition, when sulfur and accelerator DM or CZ are used together, the nitrile rubber has good tensile properties.

5. Commonly used active agent for nitrile sulfur vulcanization system

When the sulfur vulcanization system is selected for the nitrile rubber compound, zinc oxide and stearic acid are often used as vulcanization activators. The amount of zinc oxide is controlled among 1-5 parts and the amount of stearic acid is about 1 part.

When choosing sulfur-accelerator system for nitrile rubber, nitrile reclaimed rubber or nitrile rubber/reclaimed rubber combined, rubber product manufacturers must rationally design the vulcanization system to further optimize the physical and mechanical properties and service life of nitrile rubber products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits