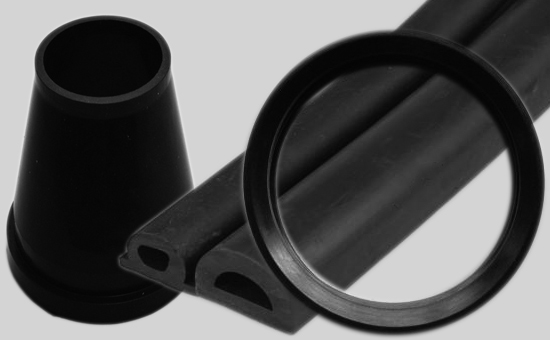

Nitrile rubber has excellent oil resistance, and the product is not easy to swell after long-term use in oily media. In addition, nitrile rubber also has good wear resistance, water resistance, air tightness and adhesion properties, and can be used to produce a variety of Oil-resistant gaskets, hoses, rubber rollers, cable sheaths, rubber sheets, gaskets, etc. When nitrile rubber is used to produce different types of rubber products, the use of nitrile rubber alone may not meet the product's physical requirements and cost budget. Therefore, nitrile rubber is often used in combination with other polymer rubber materials.

1. Natural rubber: The combined use of nitrile rubber and natural rubber can improve the processing performance and low temperature resistance of nitrile rubber; it should be noted that as the amount of natural rubber 2YLYY713 increases, the oil resistance of the combined rubber will decrease, so it must be Reasonably control the amount of natural rubber.

2. SBR: The combined use of nitrile rubber and styrene-butadiene rubber can improve the low-temperature resistance of nitrile rubber; the price of styrene-butadiene rubber is lower, and adding part of styrene-butadiene rubber can also reduce the production cost of nitrile rubber products.

3. Butadiene rubber: The combined use of nitrile rubber and butadiene rubber can improve the wear resistance, flexural resistance and low temperature resistance of nitrile rubber.

4. EPDM rubber: The combined use of nitrile rubber and EPDM rubber can improve the low temperature resistance, weather aging resistance and ozone aging resistance of nitrile rubber.

5. Neoprene: The combined use of nitrile rubber and neoprene can improve the weathering resistance of nitrile rubber.

6. Chloroether rubber: the combined use of nitrile rubber and chloroether rubber can improve the ozone aging resistance of nitrile rubber.

7. Chlorinated butyl rubber: The combined use of nitrile rubber and chlorinated butyl rubber can improve the aging resistance and corrosion resistance of nitrile rubber.

8. Chlorosulfonated polyethylene rubber: The combined use of nitrile rubber and chlorosulfonated polyethylene rubber can improve the ozone aging resistance, weather aging resistance and aging discoloration of nitrile rubber.

9. Polyvinyl chloride: The combined use of nitrile rubber and polyvinyl chloride can improve the combustion resistance of nitrile rubber.

10. ABS resin: The combined use of nitrile rubber and ABS resin can improve the wear resistance of nitrile rubber.

11. Polyamide resin: The combined use of nitrile rubber and polyamide resin can improve the abrasion resistance, low temperature resistance, oil resistance and solvent resistance of nitrile rubber.

12. Reclaimed rubber: The combined use of nitrile rubber and reclaimed rubber can significantly reduce the production cost of nitrile rubber products. In actual production, the combined use of nitrile rubber and nitrile reclaimed rubber can better ensure the oil resistance of rubber products; adding appropriate amounts of tire reclaimed rubber to nitrile wear-resistant rubber products and conductive products can reduce more raw material costs, etc. .

Adding appropriate amounts of natural rubber, other types of synthetic rubber, plastics and reclaimed rubber to the production of nitrile rubber products can not only improve the overall performance of nitrile rubber products, but also effectively reduce the cost of raw materials. Later editors will discuss related issues with you in detail.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits