Nitrile rubber + nitrile reclaimed rubber is a popular production method for nitrile products. Rubber product manufacturers can adjust the proportion of nitrile rubber and nitrile reclaimed rubber to meet different needs (mainly indicators and costs ). Manufacturers who use nitrile rubber / recycled rubber together to produce rubber products know that when the two rubber compounds are used together, nitrile rubber needs to be separately smelted sufficiently before it can be mixed with nitrile reclaimed rubber. Why? Can't nitrile rubber and nitrile rubber reclaimed at the same time?

1. Reasons for difficulties in nitrile rubber plasticizing

Nitrile rubber is a kind of synthetic rubber. It has low initial viscosity and short molecular chains. When the rubber passes through the roller gap in the rubber mixer, the molecules easily slide between them, lacking crystallization ability, and the shearing force under the same conditions is weakened. , It is difficult to break the chain, so nitrile rubber is difficult to smelt.

At the same time, under the action of mechanical force, the stability of the free radicals generated by the molecular chain of the nitrile rubber is very low, and crosslinking reactions, disproportionation reactions, etc. occur, and crosslinking reactions are likely to occur during high temperature oxidative cracking to form gels. Increased the difficulty for nitrile rubber plasticizing. The anti-aging agent used in the production process of nitrile rubber will inhibit the plasticizer 2LLYY0409, resulting in a decrease in the plasticizing effect.

2. The use of nitrile rubber / recycled rubber requires separate plastic nitrile rubber

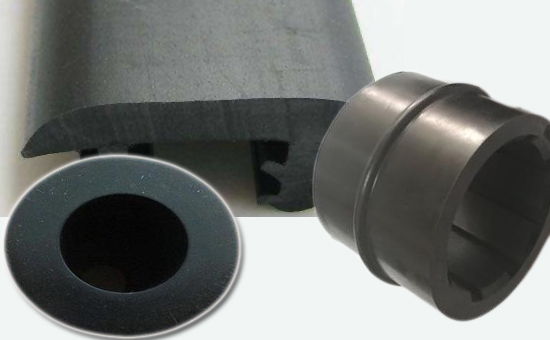

Nitrile reclaimed rubber is a new type of rubber material that has been processed through production processes such as vulcanization, mixing, oxidation, and compression. It has good fluidity, good plasticity, low power consumption during mixing, and can be mixed in a short time. Molding; nitrile rubber is difficult to smelt. If it cannot be smelted in advance, it is difficult to evenly mix with nitrile reclaimed rubber, which will affect the quality of the nitrile rubber products.

3. Selection of nitrile butadiene rubber refining process equipment

When nitrile rubber products manufacturers plasticize raw rubber, gels are easily generated under high-temperature plasticizing conditions, so avoid using a mixer to make nitrile rubber as much as possible. According to the initial Mooney viscosity, nitrile rubber can be divided into soft nitrile rubber and hard nitrile rubber. Among them, hard nitrile rubber has very high toughness, and generates much heat and shrinks vigorously during the plasticizing process, which seriously affects the rubber compounding effect. It is best to use the low-temperature thin-pass method for plasticizing. During the plasticizing process, the roller temperature should be controlled between 30-40 ° C and the roller distance should be controlled between 0.5-1mm. Cool in time to improve the plasticizing effect.

Many factors lead to difficulties in the plasticization of nitrile rubber. Therefore, when using nitrile rubber and nitrile reclaimed rubber together to produce rubber products, nitrile rubber must be separately smelted. After sufficient smelting, it can be mixed with reclaimed rubber to ensure the quality of nitrile rubber / recycled rubber products and avoid unnecessary Cost losses.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits