EPDM reclaimed rubber uses waste EPDM rubber products such as EPDM sealing strip as raw material, and after selection, desulfurization, filtration and refining, the desulfurization has the greatest impact on the quality of reclaimed rubber products. Common EPDM reclaimed rubber desulfurization methods include steam desulfurization, cooking desulfurization, mechanical desulfurization, chemical desulfurization, microwave desulfurization and so on. Microwave desulfurization method which belongs to the physical method, is in the research stage.

EPDM reclaimed rubber steam desulfurization method is the use of hot steam temperature and external pressure desulfurization of reclaimed rubber, including reclaimed rubber oil desulfurization, reclaimed rubber superheated steam desulfurization, reclaimed rubber high pressure desulfurization, regenerative acid desulfurization, etc .; water and oil The method, the neutral method and the alkaline method belong to the cooking desulfurization method. Compared with the steam desulfurization method, the mechanized degree is high, and the reclaimed rubber produced is more stable in performance. The mechanical desulfurization method uses the mechanical friction extrusion to form the temperature and the pressure for desulfurization. A common method There are mixer desulfurization, twin-screw extrusion, rapid desulfurization, spiral dynamic desulfurization, etc .; chemical desulfurization principle is through the chemical reaction to dispel the sulfur in rubber waste, dissolved desulfurization, grafting desulfurization, disperse desulfurization Method, plasticizing desulfurization method, the method of complex high cost and difficult to control.

When using microwave desulfurization method to produce EPDM reclaimed rubber, the S-S and S-C bonds are selectively cut off to achieve the purpose of regeneration. Generally, only sulfur-cured EPDM rubber can adopt microwave regeneration method, and carbon black can be added in the desulfurization process to increase the polarity and reaction temperature of the rubber. When using the microwave desulfurization method to produce EPDM reclaimed rubber, it must be selected A suitable condition to break the SS bond or SC bond as much as possible without breaking a large number of polymer main chains to ensure that the EPDM retains more ethylene propylene rubber properties.

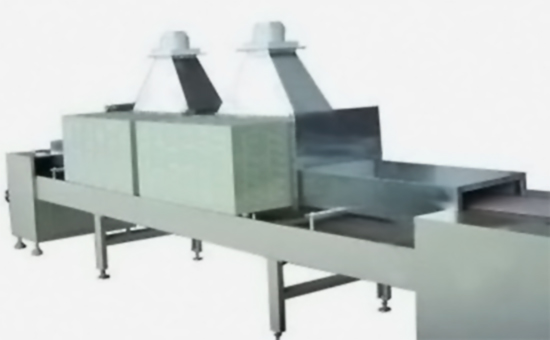

Hebei Hongyun Reclaimed Rubber Factory production of EPDM renewable rubber using the latest infrared dynamic desulfurization after 60 mesh dual-channel filtration molding, retains the original molecular weight and more than 90% of the rubber chain structure, high temperature resistance, anti-aging, high insulation , Corrosion resistance, high strength, good elasticity, smooth and bright surface of the product, save energy, open process is simple, can reduce the cost of raw materials of rubber products about 20%.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits