In the process of tire reclaimed rubber production, desulphurization is the most important process: The finished tire rubber powder is the raw material for the reclaimed rubber tire. The rubber powder before being desulfurized is in a fluffy state without any adhesiveness and only After desulfurization, tire rubber powder again with plasticity, adhesion. After the desulfurization of the tire powder through the mixer and mixer after rolling molding tire reclaimed rubber, put on the market.

At present, there are mainly two kinds of tire reclaimed rubber desulfurization methods: physical microwave method, chemical high temperature dynamic desulfurization tank method and normal temperature continuous desulfurization method.

Microwave desulfurization is the key to desulfurization by controlling the strength of the microwave field and destroying the molecular bonds of the discarded tires. The use of microwave desulfurization regeneration rubber production process without adding regenerative activator, desulfurization time is short, high efficiency, but will produce some pollution.

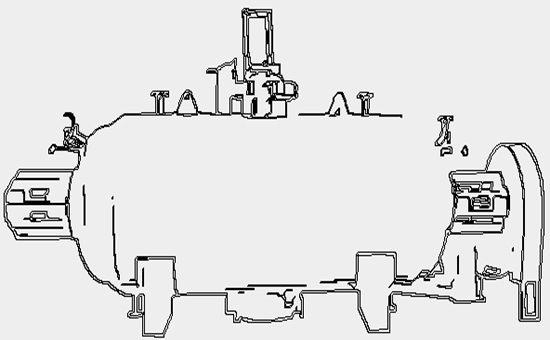

The chemical high temperature dynamic desulfurization tank is the main method of desulfurization for tire regeneration in our country. After pulverizing waste tires in rubber powder, the rubber powder and desulfurization rubber powder and a certain proportion of regenerant (ie activator and softener) Tank reaction, pressure, heating, water desulfurization, the waste rubber powder desulfurization in renewable rubber powder, the production of tire reclaimed rubber. Dynamic desulfurization tank process can not be continuous production, product quality is not easy to control, time-consuming and labor-intensive, high production costs, high pressure will lead to tank wall thinning and thus lead to accidents, water vapor and added softener complex chemical reaction will lead to difficult Smell the exhaust gas, there is a certain degree of environmental pollution, there are some potential safety problems, has been phased out.

The tire rubber powder in the continuous desulfurization method at room temperature reacts in the pipeline. The rubber powder desulphurizes during the constant agitation. For example, the continuous desulphurization of multi-stage screw can be replaced by "machine replacing tank", which is safer and less polluting.

Both the physical microwave desulfurization method, chemical high-temperature dynamic desulfurization tank or continuous desulfurization at room temperature have their own advantages and disadvantages, and now with the development of reclaimed rubber production technology, tire reclaimed rubber desulfurization methods are also more and more, the type of tire reclaimed rubber Performance is getting better.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits