Natural latex recycled rubber is processed from waste natural rubber, waste latex and its products as raw materials, with the basic performance characteristics of natural rubber, high mechanical strength, good elasticity, wear resistance, aging resistance, can be used alone or with natural rubber, general synthetic rubber combined with the production of various sports rubber products, effectively reduce the cost of raw materials under the premise of ensuring the performance of finished products. The application of latex reclaimed rubber in sporting goods mainly includes table tennis racket rubber, rubber ball, sports equipment grip, yoga mat, etc.

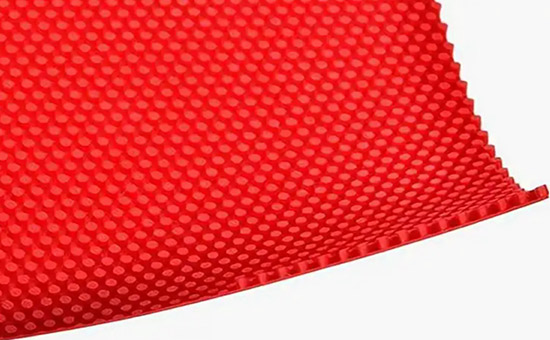

1. Table tennis racket vinyl surface

Table tennis racket is one of the important sports equipment, which is generally made of granular rubber surface (positive rubber surface and reverse rubber surface), sponge and bottom plate bonding. The rubber surface of the table tennis racket is generally processed with high elasticity natural rubber as the main raw material, and the appropriate amount of latex reclaimed rubber is mixed with it, which can effectively reduce the production cost. When natural rubber/latex reclaimed rubber is used together to produce table tennis racket rubber surface, sulfur-accelerator system is mostly used, and the accelerators M, DM, D, TT and CZ are commonly used with sulfur, non-polluting antioxidants are selected, and calcium carbonate and silica are commonly used as reinforcing fillers.

The rubber performance requirements of the positive rubber surface and the reverse rubber surface of the table tennis racket are different, and the formula is obviously different when natural rubber/latex reclaimed rubber is used together to prepare different rubber surfaces. Under normal circumstances, the glue content of the positive rubber surface of the table tennis racket is among 60% and 70%, which requires the rubber to have high hardness, moderate elasticity and certain aging resistance; The glue content of the rubber on the reverse rubber surface is higher than 85%, which requires the rubber to have moderate hardness, large elasticity, small hysteresis damage, and certain aging resistance.

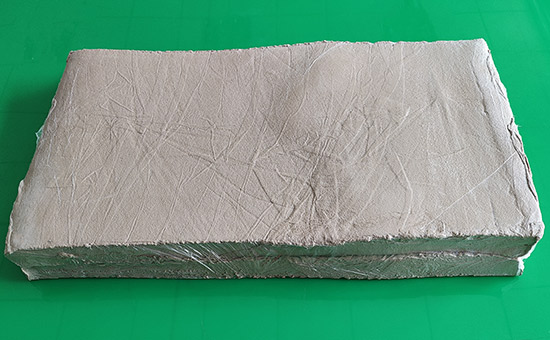

2. Universal rubber balls

Rubber balls are typical hollow rubber molded products, which can be divided into gallbladder balls (with skeleton layer and without skeleton layer) and gallbladder balls, which have good elasticity after inflation, long service life and no water absorption. General rubber balls require good air tightness, good elasticity, soft feel, no slippage, and a certain degree of wear resistance, generally based on natural rubber, butadiene rubber, styrene-butadiene rubber, mixed with latex reclaimed rubber can effectively reduce the cost of raw materials.

The rubber skin of the rubber ball is generally controlled among 40% and 50%, and the sulfur-accelerator system is mostly used after mixing latex reclaimed rubber; With the use of silica and clay, improve the wear resistance of the rubber material; Resins such as rosin, coumarone resin, resorcinol E4LYY918 are used to improve adhesion; Combined with the use of non-polluting antioxidants, improve the aging resistance of the finished product. Using natural rubber as the main raw material to produce rubber bulbs, and an appropriate amount of ultra-fine latex reclaimed rubber can further improve the processing performance of rubber and the aging resistance of finished products.

3. Sports equipment grips

Sports equipment grip refers to the handle part that is installed on sports equipment (such as dumbbells, barbells, rackets, gym equipment, etc.), which is mainly used to provide comfort, slip resistance, and durability for grip and operation. Natural rubber has good elasticity and abrasion resistance, and is often used to make non-slip grips; Latex reclaimed rubber has the basic performance characteristics of natural rubber, the price is much lower than that of natural rubber, and can be used with natural rubber to produce sports equipment grips, reduce the cost of raw materials, improve aging resistance, and the grip is not easy to harden and slip due to frequent contact with sweat and air in the process of long-term use.

Latex reclaimed rubber can also be used in the production of yoga mats, sports soles and other occasions. When using latex reclaimed rubber in the production of sporting goods to reduce costs, we must choose the appropriate latex reclaimed rubber according to the use environment and cost budget of the product, and reasonably determine the proportion of natural reclaimed rubber. In the follow-up, Xiaobian will share with you the vulcanization formula of sporting goods containing latex reclaimed rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits