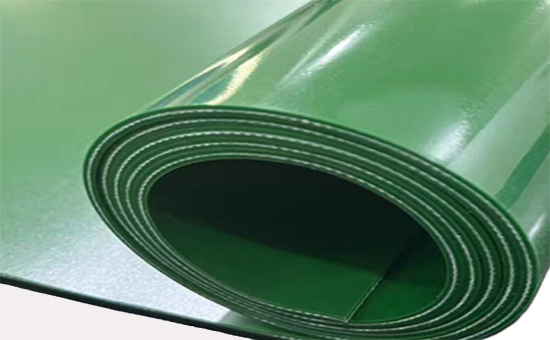

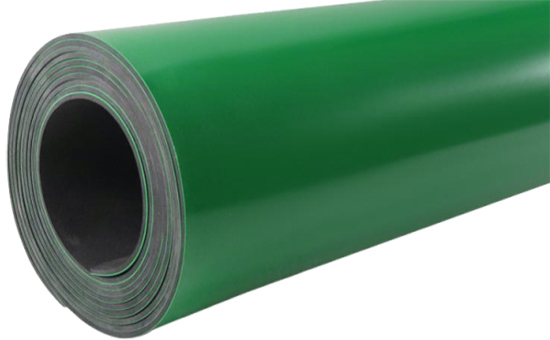

Green ordinary rubber plate is a sheet green rubber product with a certain thickness and area made of natural rubber, styrene-butadiene rubber, butadiene rubber, etc. as the main raw material, and the glue content is about 30%; The appropriate use of reclaimed rubber can effectively reduce the cost of raw materials. Latex reclaimed rubber is a product of desulfurization and regeneration of waste natural rubber and waste latex products, which has the basic performance characteristics of natural rubber, and can replace part of the original rubber to produce green ordinary rubber sheets, and the reasonable design formula can further optimize the comprehensive performance of rubber sheets while reducing costs.

1. Natural rubber/latex reclaimed rubber is used to produce green ordinary rubber plate vulcanization formula

50 parts of natural rubber, 50 parts of latex reclaimed rubber, 3.5 parts of zinc oxide, 1.3 parts of stearic acid, 1 part of antioxidant SP, 1.5 parts of paraffin, 45 parts of light calcium carbonate, 135 parts of stone powder, 10 parts of titanium dioxide, 1 part of phthalocyanine green, 0.7 parts of sunfast alcohol soluble yellow, 6 parts of petroleum jelly, 0.3 parts of accelerator D, 0.7 parts of accelerator DM, 1.5 parts of sulfur; Total 307.5 copies.

2. Green ordinary rubber board mixed with latex reclaimed rubber selection skills

When using latex reclaimed rubber to replace some natural rubber, butadiene rubber, etc., to produce green ordinary rubber sheets, it is necessary to comprehensively consider the color, physical and mechanical properties of the product, cost budget and other aspects. In general, it is recommended to choose white latex reclaimed rubber for colored rubber products, which is light in color, easy to match and not easy to change color; When the green rubber sheet is mixed with reclaimed rubber, green latex reclaimed rubber can also be selected.

After mixing latex reclaimed rubber, the green ordinary rubber plate can not only reduce the cost of raw materials, but also improve the processing technology performance of the rubber compound, the specific performance: the plasticity of the rubber compound increases, the compounding agent is easy to disperse evenly, and the powder is fast, so the mixing time is short, the rolling and shrinkage of the rubber are improved, the vulcanization return to the original is small, and the heat resistance of the vulcanized rubber is better.

3. Green ordinary rubber board mixed with latex reclaimed rubber formula adjustment skills

(1) Vulcanization system

When the sulfur-accelerator system is used to produce green ordinary rubber sheets by combining natural rubber/latex reclaimed rubber, the amount of sulfur can be increased by 5% - 15%; The combination of thiazole accelerator and guanidine accelerator can accelerate the vulcanization speed, improve the crosslinking efficiency, and appropriately adjust the accelerator dosage according to the sulfur dosage and rubber compound characteristics, the dosage of thiazole accelerator can be increased by 5% - 10%, and the comprehensive performance of green rubber plate is better.

(2) Reinforcement filling system

In the reinforcing filling system of ordinary green rubber board, it is recommended that light-colored reinforcing agents and fillers be used preferentially, such as light calcium, clay, etc.; When using silica to improve natural rubber/latex reclaimed rubber and using rubber compound to E4LYY93 mechanical strength and elasticity, 5-10 parts of silica are combined with 0.5-1 parts of silane coupling agent to improve dispersibility. When the ordinary green rubber board containing latex reclaimed rubber must be reinforced with carbon black, it is recommended to choose carbon black with moderate particle size and high structure, such as N330 carbon black, which can not only provide reinforcement effect, but also have little impact on color.

(3) Softening plasticizing system

Use softeners and plasticizers in an appropriate amount, such as naphthenic oil, paraffin oil, petroleum jelly, etc., to improve the processing performance and flexibility of rubber compounds, make natural rubber and latex reclaimed rubber compounds easier to mix and form, and try to avoid the use of aromatic hydrocarbon oils.

In the production of green ordinary rubber sheets with natural rubber as the main raw material, rubber plate manufacturers can choose the appropriate latex reclaimed rubber according to the actual needs, appropriately adjust the addition ratio of natural rubber and latex reclaimed rubber, as well as the variety and dosage of compounding agent, so as to further improve the comprehensive performance of the rubber plate and reduce production costs. In the future, Xiaobian will continue to share with you the key points of natural rubber and latex reclaimed rubber combined to produce green ordinary rubber sheet mixing and vulcanization.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits