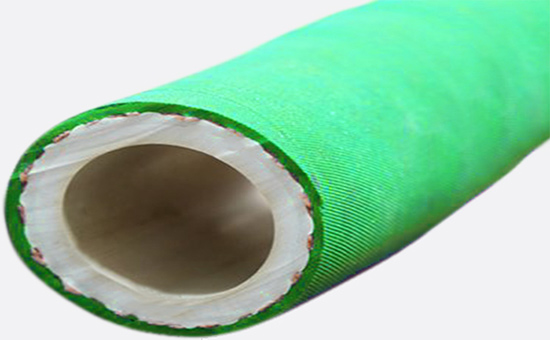

Rubber pipes are mainly used to transport various gases, liquids, viscous fluids and solid particles, etc., and are widely used in various fields such as industry, agriculture, energy, and transportation. Among them, colored rubber pipes are generally processed with light-colored natural rubber as the main raw material; latex reclaimed rubber has the basic performance characteristics of natural rubber, and can be mixed into the production of natural rubber colored rubber pipes, effectively reducing the cost of raw materials on the premise of ensuring product quality.

1. Purchase points of latex reclaimed rubber for color hoses

When using latex reclaimed rubber to reduce the production cost of natural rubber colored hoses, it is generally necessary to comprehensively consider the physical and mechanical performance indicators, color, cost budget and other factors of the rubber hose, and select latex reclaimed rubber that is close to its indicators. Latex reclaimed rubber can be divided into white latex reclaimed rubber, black natural reclaimed rubber, yellow latex reclaimed rubber, red latex reclaimed rubber, green latex reclaimed rubber, etc.; color hoses can choose suitable color latex reclaimed rubber; among them, white latex reclaimed rubber Light color, easy color matching, can be used to produce colored hoses of various colors.

2. Production formula of colored rubber hose mixed with latex reclaimed rubber

50 parts of natural rubber, 50 parts of white pure latex reclaimed rubber, 5 parts of zinc oxide, 1 part of stearic acid, 1 part of antioxidant, 40 parts of activated calcium carbonate, 5 parts of titanium dioxide, 1.2 parts of accelerator DM, 0.3 part of accelerator TMTD , 1.75 parts of sulfur, 0.75 parts of colorant; total: 156 parts.

50 parts of natural rubber, 50 parts of white pure latex reclaimed rubber, 5 parts of zinc oxide, 1 part of stearic acid, 1 part of antioxidant, 40 parts of activated calcium carbonate, 5 parts of titanium dioxide, 0.95 parts of accelerator DM, 0.3 part of accelerator TMTD , 0.75 part of colorant; total: 154 parts.

3. Formulation design of color hose mixed with latex reclaimed rubber

When using latex reclaimed rubber to produce colored hoses, sulfur vulcanization system or sulfur-free vulcanization system is often used, in which the amount of sulfur can be increased appropriately, and an increase of 20% of the amount of sulfur 2ELYY719 will not bloom like natural rubber. In the reinforcement and filling system, the use of activated calcium carbonate can improve the elongation, tensile strength, tear strength, etc. of the color latex reclaimed rubber hose, and play multiple functions of reinforcement, filling and color matching. Anti-aging agent It is recommended to use non-polluting anti-aging agent to avoid discoloration and migration.

When using latex reclaimed rubber to produce colored hoses, it is necessary to select the appropriate latex reclaimed rubber according to actual needs. It is recommended to use high-strength and environmentally friendly latex reclaimed rubber. Migration occurs during production and use. Later, the editor will continue to share with you the key points of the production process of colored rubber hose mixed with latex reclaimed rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits