Latex reclaimed rubber can be used alone or in combination with natural rubber and other general-purpose rubbers, effectively reducing production costs. Sponge foam rubber products are a general term for rubber products with a perforated structure. They have the advantages of light texture, good elasticity, and significant heat insulation and shock absorption effects. Natural rubber, styrene butadiene rubber, butadiene rubber, nitrile rubber, butyl rubber, and Ethylene-propylene rubber can be used to produce foamed rubber products. Can latex reclaimed rubber be used in the production of sponge foam rubber? Which sponge rubber products can use latex reclaimed rubber?

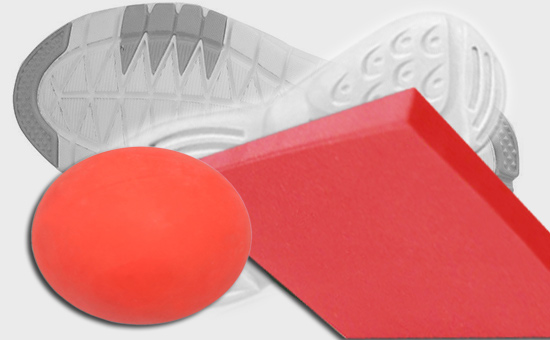

1. Sponge foam sole

The sponge foam rubber sole is light and soft, and has a good shock absorption effect. Traditional foam rubber soles generally use natural rubber as the main raw material, and an appropriate amount of styrene-butadiene rubber is added to improve the abrasion resistance of the rubber soles. Reclaimed latex rubber can be used in the production of various sponge foam rubber soles such as sports soles, effectively reducing the cost of raw materials.When using reclaimed latex rubber to produce sponge rubber soles, it is recommended to choose environmentally friendly reclaimed latex rubber, and use white latex reclaimed rubber for colored soles.

2. Sponge styrofoam board

The high-quality reclaimed latex rubber has high effective rubber hydrocarbon content, which can directly replace natural rubber to produce sponge foam rubber flooring, which is widely used in homes, factories, fitness places, public places, etc. When using latex reclaimed rubber 2YLYY99 to produce low-cost sponge foamed rubber flooring, it is recommended to use environmentally friendly latex reclaimed rubber that has passed EU ROHS. It has no harmful substances, no irritating smell, and no penetration. It can be used alone or with appropriate amount of natural rubber and styrene-butadiene rubber. The combined use of rubber reduces costs while ensuring product quality.

3. Microcellular foam tires

Microcellular foam tires have the characteristics of good cushioning performance, high driving safety, and puncture resistance. The microcellular foamed tire produced by mixing latex reclaimed rubber with appropriate amount of vulcanizing agent, accelerator, foaming agent, filler, softener, activator and other compounding agents has low cost, stable performance and long service life.

4. Colored sponge foam ball

The colored sponge foam ball has bright colors, small smell, good elasticity and soft touch. The use of latex reclaimed rubber instead of natural rubber can effectively reduce the production cost of the foam ball. Latex reclaimed rubber is recommended to use white latex reclaimed rubber when producing colorful foamed rubber balls, which is easy to match colors and does not migrate; choose latex reclaimed rubber with high rubber content to ensure the elasticity and softness of the foamed ball; choose environmentally friendly latex reclaimed rubber, Odorless latex reclaimed rubber, non-irritating odor, non-toxic and harmless.

5. Sponge styrofoam strip

Latex reclaimed rubber can replace part of the high-priced raw rubber used in the production of foam styrofoam strips, effectively reducing the cost of raw materials and improving the process performance of the rubber. When using latex reclaimed rubber to produce foam styrofoam strips, it is recommended to use filtered latex reclaimed rubber, which has high fineness and no impurities to ensure smooth foaming and extrusion of styrofoam strips. Among them, colored styrofoam strips can use white latex reclaimed rubber, which is easy to match colors; black and dark styrofoam strips use black latex reclaimed rubber, which is lower in cost.

Latex reclaimed rubber can also be used in the production of other sponge rubber products, effectively reducing the cost of raw materials under the premise of ensuring the quality of sponge foam rubber. Due to space limitations, the editor will not list them one by one, and will continue to discuss related issues with you later.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits