The use of reclaimed latex rubber in the production of rubber sheets with natural rubber as the main raw material can not only ensure the physical and mechanical properties of the rubber sheets, but also significantly reduce the cost of raw materials. When using latex reclaimed rubber/natural rubber to produce rubber sheets, the rubber sheet production process directly affects the performance and life of the finished product. Rubber sheet manufacturers need to strictly control each production process to avoid improper operation that affects the quality of the finished rubber sheet.

1. Weighing and processing raw and auxiliary materials: When using latex reclaimed rubber/natural rubber combined with rubber to produce rubber sheets, you must first weigh all rubber raw materials and rubber additives according to the formula; mix sulfur, mica powder 2LLYY1231 and other powders in advance The agent is pre-dispersed to prevent uneven dispersion of the compounding agent from causing problems such as over-sulfur, under-sulfur, and air bubbles in the compound; this process is generally carried out in a mixer.

2. Pretreatment of reclaimed latex rubber: refining and filtering the reclaimed latex rubber. After filtering the reclaimed latex rubber once, the reclaimed rubber can be put into the internal mixer for 3-5 minutes for secondary filtration; then the filtered latex The reclaimed rubber is put into the refiner, and the roll distance of the refiner is adjusted to about 0.3mm for refining for 3-5 minutes.

3. Fully masticated natural rubber: put the natural rubber into the internal mixer for mixing for about 7 minutes; then put the natural rubber after mixing to a certain degree into the open mixer, adjust the roller distance to about 5mm, and mix 2 -3min.

4. Latex reclaimed rubber/natural rubber mixing: Put natural rubber and latex reclaimed rubber into an internal mixer for banburying for 2-3 minutes, then add half of the zinc oxide, stearic acid, paraffin, clay and other compounding agents to continue banburying 3- 5min, add the remaining half of the small material and ban it for about 0.5min.

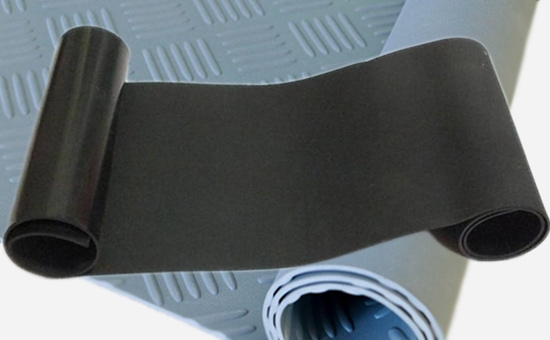

5. Calendering, cooling and vulcanization: After mixing the latex reclaimed rubber/natural rubber, put the rubber into the calender for calendering; cooling treatment after calendering; fully cooled latex reclaimed rubber/natural rubber combined with rubber vulcanization process is general It is carried out in a drum vulcanizer, and the vulcanization temperature, vulcanization time, vulcanization pressure and other parameters are appropriately adjusted to vulcanize and shape.

When using latex reclaimed rubber/natural rubber combined rubber to produce rubber sheets, rubber product manufacturers not only need to choose suitable rubber raw materials (the price of black latex reclaimed rubber with the same index is lower, and the color matching of white latex reclaimed rubber is easier), and the rubber product formula is rationally designed , Also need to strictly control the production process. Timely mastering the production process and strictly controlling the production process parameters can better guarantee the yield and quality of the latex reclaimed rubber/natural rubber sheet, and avoid unnecessary losses.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits