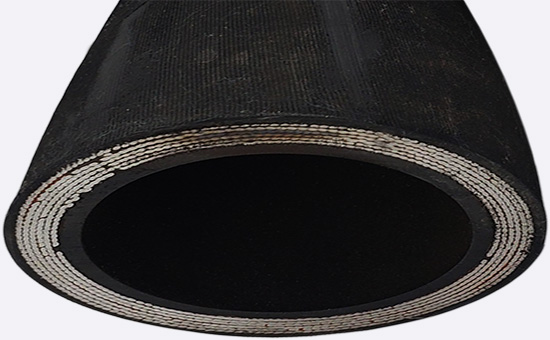

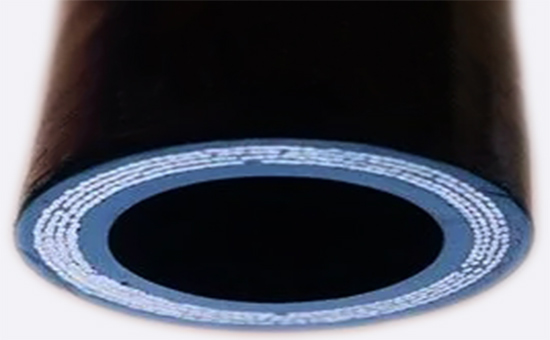

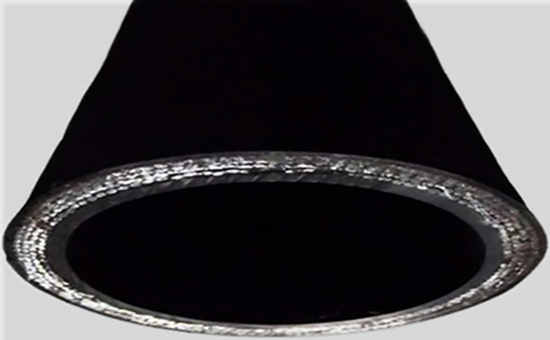

Buried suction hose is widely used in agricultural drainage and irrigation, industrial and mining, water conservancy, food processing and other fields, mainly used to absorb liquid, powdery granular solid materials or inert gas under negative pressure, usually composed of inner rubber layer, adhesive tape layer, metal spiral, intermediate rubber layer, outer rubber layer; The middle layer of rubber is mainly used to connect the inner rubber layer and the adhesive cloth layer to ensure the overall bonding and sealing, generally using natural rubber and styrene-butadiene rubber as the main raw materials, and the use of tire reclaimed rubber can effectively reduce the cost of raw materials.

1. The performance requirements of the middle layer of the thread suction hose

The middle layer of the thread suction hose not only needs to provide sufficient adhesion to ensure the firm combination of the inner and outer adhesive layers and the skeleton layer, but also needs to have certain pressure resistance and aging resistance to ensure the stability and reliability of the hose during long-term use. Therefore, the middle layer of the suction hose requires the rubber compound to have good adhesion, pressure resistance, aging resistance, chemical corrosion resistance and processing performance, and the processing performance includes the adaptability of mixing, calendering, molding and vulcanization.

2. The role of rubber raw materials and rubber accessories in the middle rubber formula of the buried suction hose

In the formula of the buried suction hose containing tire reclaimed rubber, natural rubber can provide good elasticity and adhesive properties, styrene-butadiene rubber can improve the wear resistance and pressure resistance of the hose, and recycled rubber 2SLYY1214 can effectively reduce the cost of raw materials (tire tread reclaimed rubber has high mechanical strength and good elasticity, which can better ensure the quality of the buried hose). The filler in the thread suction hose formulation can not only increase the volume of the compound, improve the processing performance and reduce the cost; Filler and adhesive combinations can enhance the adhesion to the skeleton layer.

In addition, the middle layer of the buried suction hose containing tire reclaimed rubber also needs to choose a suitable vulcanization system to ensure that the hose has good mechanical properties and heat resistance; Use antioxidants in moderation to further extend the service life of the hose.

3. The middle layer of the buried suction hose is mixed with the practical formula of tire tread reclaimed rubber

(1) 50 parts of natural rubber, 50 parts of styrene-butadiene rubber, 70 parts of tread reclaimed rubber, 4 parts of zinc oxide, 2 parts of stearic acid, 1.5 parts of antioxidant D, 40 parts of carbon black N660, 55 parts of calcium carbonate, 70 parts of clay, 20 parts of softened heavy oil, 5 parts of asphalt, 1.2 parts of accelerator DM, 0.3 parts of accelerator TMTD, 2.5 parts of sulfur; total: 371.5 parts.

(2) 50 parts of natural rubber, 50 parts of styrene-butadiene rubber, 80 parts of tread reclaimed rubber, 5 parts of zinc oxide, 2 parts of stearic acid, 1.5 parts of antioxidant D, 46 parts of carbon black N660, 50 parts of light calcium, 65 parts of clay, 18 parts of softened heavy oil, 8 parts of asphalt, 1 part of accelerator CZ, 0.3 parts of accelerator TMTD, 2.5 parts of sulfur, total: 379.3 parts.

(3) 50 parts of natural rubber, 50 parts of oil-filled styrene-butadiene braid, 70 parts of tread reclaimed rubber, 4 parts of zinc oxide, 2 parts of stearic acid, 1.5 parts of antioxidant D, 55 parts of carbon black N660, 40 parts of light calcium, 70 parts of clay, 20 parts of softened heavy oil, 5 parts of asphalt, 1.2 parts of accelerator DM, 0.3 parts of accelerator TMTD, 2.2 parts of sulfur; total: 371.2 copies.

When designing the middle rubber formula of the buried suction hose containing tire reclaimed rubber, it is necessary to comprehensively evaluate the expected use environment and performance indicators of the hose, select appropriate rubber raw materials, and reasonably design the formula to ensure the quality and performance of the hose. In actual production, tire reclaimed rubber can also be appropriately mixed in the preparation of other adhesive layers of the buried suction hose to reduce costs without sacrificing product performance.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits