Tire reclaimed rubber is made of waste tire rubber as the main raw material, processed by crushing, sorting, desulfurization, filtration, refining and other processes, with a certain plasticity and viscosity, can be processed and vulcanized, and can be recycled into the production of rubber products, such as tire tires, rubber sheets, hoses, etc., effectively reducing production costs. When tire reclaimed rubber is used in rubber products, the physical properties of tire reclaimed rubber directly affect the quality of the finished product. Xiaobian today to share with you the tire reclaimed rubber testing formula and testing sequence.

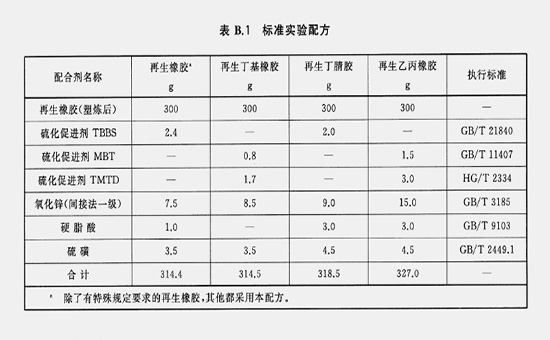

1. Tire reclaimed rubber testing formula

Tire reclaimed rubber 300g, accelerator TBBS 2.4g, indirect zinc oxide 7.5g, stearic acid 1g, sulfur 3.5g, total: 314.4g. The above formula is from GB/T 13460-2016 "Recycled Rubber".

2. Tire reclaimed rubber testing procedure

(1) Plasticizing: Put the tire reclaimed rubber sample into the rubber mixer, pass it through the roller 3 times, and then cool it to room temperature.

(2) Mixing: Put the sample of tire reclaimed rubber after plastic refining into the rubber mixer, add the compounding agent, mix it evenly, thin it, release the film, and cool it to room temperature.

(3) Vulcanization: The vulcanization test piece is vulcanized at a temperature of 145 °C±1 for 10min, 15min and 20min respectively, and then the tensile strength and tearing elongation of the tire recycled rubber are measured, and the value of the best vulcanization time is taken.

In practical application, rubber product manufacturers can test tire reclaimed rubber according to this standard to ensure that its performance meets production needs. The inspection is generally carried out in the open rubber mixer, and the roll temperature is controlled at (40±5) °C, the roll distance is (1.5±0.1) mm, and the distance among the two baffles is (150±20) mm; The sample is put into the rubber mixer and completely passed through the roller 3 times, and the rubber is placed on a flat, clean and dry metal surface to cool to room temperature after plasticization.

In addition, the testing of tire reclaimed rubber also includes moisture, ash, acetone extract, tensile strength, elongation at break, Mooney viscosity, Shore hardness and other indicators, which are important indicators to measure the quality and applicability of tire reclaimed rubber. When using tire reclaimed rubber to produce rubber products, you can take a small piece of reclaimed rubber 2SLYY124 for testing, and select the product that best meets the requirements of the performance index of rubber products, so as to reduce more costs on the premise of ensuring the quality of finished products. The rational use of tire reclaimed rubber not only has good economic benefits, but also helps to reduce the environmental pollution caused by waste rubber and alleviate the shortage of natural rubber resources.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits