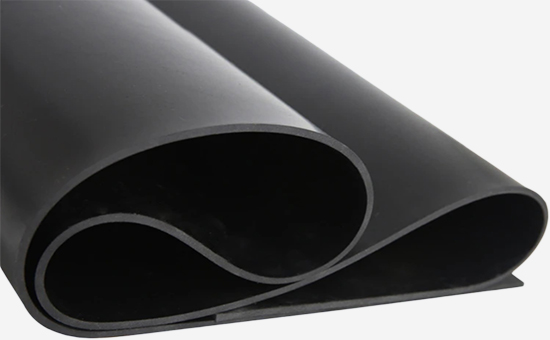

Rubber sheets are widely used in various fields such as construction, automobiles, electronics, ships, etc., requiring the rubber materials used to have good elasticity, wear resistance, aging resistance, electrical insulation and certain chemical corrosion resistance. Tire reclaimed rubber 2SLYY1226 is a renewable resource for recycling and reprocessing waste tires, and its main components are natural rubber, general synthetic rubber, and carbon black, which can be re-added to the production of rubber sheets to reduce costs.

1. The advantages of natural rubber production rubber sheet mixed with tire reclaimed rubber

When using natural rubber, natural rubber/styrene-butadiene rubber to produce rubber sheets, the rational use of tire reclaimed rubber can not only significantly reduce the cost of raw materials, but also improve the process performance and finished product performance. Specifically, it is manifested in the following aspects:

(1) Tire reclaimed rubber has good plasticity and fluidity, and is easy to mix with raw rubber and compounding agent, which can improve the processing performance of rubber compound.

(2) Compared with pure natural rubber rubber, the rubber material mixed with tire reclaimed rubber to produce rubber sheet has less heat generation in the process of mixing, hot mixing, extrusion, calendering, etc., which can effectively avoid the scorching phenomenon caused by high rubber temperature.

(3) Tire reclaimed rubber has undergone intense treatment such as vulcanization, mixing and oxidation during processing, and the rubber hydrocarbons have been in a stable state, with better aging resistance, weather resistance, acid and alkali resistance. Therefore, the use of tire reclaimed rubber in the formulation of natural rubber sheet can prolong the service life of rubber sheet.

(4) The use of waste tires to produce reclaimed rubber helps to reduce the pressure of waste rubber on the environment and meets the requirements of sustainable development.

2. Reference formula for the production of 70-degree rubber sheets by mixing tire reclaimed rubber

(1) 100 parts of natural rubber, 40 parts of tire reclaimed rubber, 6 parts of zinc oxide, 2.5 parts of stearic acid, 1.5 parts of antioxidant D, 20 parts of carbon black N774, 180 parts of stone powder, 10 parts of pine tar, 0.7 parts of accelerator D, 1.2 parts of accelerator M, 2.5 parts of sulfur; Total 364.4.

(2) 50 parts of natural rubber, 50 parts of styrene-butadiene rubber, 30 parts of tire reclaimed rubber, 6 parts of zinc oxide, 2.5 parts of stearic acid, 0.5 parts of antioxidant A, 0.5 parts of antioxidant D, 5 parts of paraffin, 25 parts of carbon black N330, 50 parts of stone powder, 60 parts of light calcium, 6 parts of engine oil, 3 parts of pine tar, 0.5 parts of accelerator D, 2.5 parts of accelerator M, 2.5 parts of sulfur; Total 294 copies.

(3) 100 parts of natural rubber, 30 parts of tire reclaimed rubber, 5 parts of zinc oxide, 2 parts of stearic acid, 1 part of antioxidant A, 1 part of paraffin, 35 parts of carbon black N330, 100 parts of light calcium carbonate, 110 parts of barite powder, 14 parts of liquid coumarone, 0.7 parts of accelerator D, 1.5 parts of accelerator DM, 1.8 parts of sulfur; 402 in total.

3. Key points of natural rubber rubber plate mixed with tire reclaimed rubber formula

(1) By increasing the amount of sulfur, the vulcanization cross-linking density of natural rubber/tire reclaimed rubber can be improved, so as to improve the chemical resistance of rubber sheets.

(2) By adjusting the dosage of reinforcing filler and non-reinforcing filler varieties in the formula, rubber sheets of different hardness can be prepared by tire reclaimed rubber to meet the needs of different use occasions.

(3) When using natural rubber/tire reclaimed rubber and glue to produce rubber sheets with certain requirements for acid and alkali resistance, it is recommended to use chemically inert rubber fillers such as clay, barium sulfate, talc, diatomaceous earth, etc., and avoid using water-soluble fillers and fillers with high moisture content.

When using tire reclaimed rubber in the rubber sheet formula produced by natural rubber, natural rubber/styrene-butadiene rubber combined rubber to reduce costs, it is also necessary to adjust the production process and various process parameters to adapt to the characteristics of reclaimed rubber; The rational use of tire reclaimed rubber in different varieties of rubber sheets can achieve the dual goals of cost control and environmental protection.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits