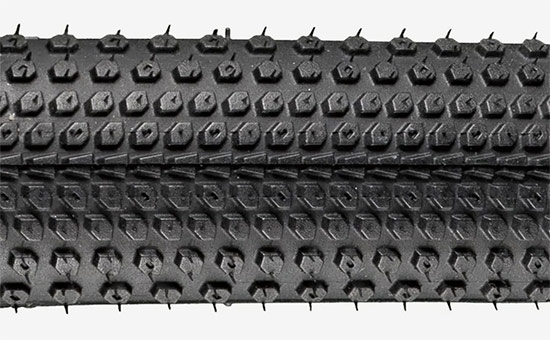

Bicycle tire tread rubber is the outermost layer of bicycle tire in direct contact with the road surface, the surface with patterns of the layer of rubber, requiring the rubber to have good wear resistance, flex resistance, puncture resistance, as well as good tensile strength, tear strength, etc., generally processed with natural rubber as the main raw material; The appropriate amount of vulcanized rubber powder can not only reduce the cost of raw materials, but also improve the processing technology performance of rubber compounds, and improve the tear resistance and aging resistance of finished products.

1. Natural rubber/vulcanized rubber powder produces vulcanized formula for bicycle tire tread rubber

100 parts of natural rubber, 10 parts of vulcanized rubber powder, 5 parts of zinc oxide, 3 parts of stearic acid, 0.75 parts of antioxidant A, 0.75 parts of antioxidant D, 35 parts of carbon black N330, 15 parts of light calcium carbonate, 8 parts of clay, 1 part of paraffin, 3 parts of coal tar, 0.1 parts of accelerator TMTD, 1.4 parts of accelerator M, 2.6 parts of sulfur; Total 185.6 copies.

2. Natural rubber/reclaimed rubber/vulcanized rubber powder produces vulcanized formula for bicycle tire tread rubber

Formula 1: 90 parts of natural rubber, 10 parts of reclaimed rubber, 10 parts of vulcanized rubber powder, 7.5 parts of zinc oxide, 1 part of paraffin, 1 part of antioxidant A, 32 parts of carbon black N330, 15 parts of carbon black N774, 7 parts of light calcium carbonate, 7.5 parts of pine tar, 1 part of accelerator M, 0.2 parts of accelerator D, 0.15 parts of accelerator D, 0.05 parts of accelerator TMTD, 2.7 parts of sulfur; Total 185.1 copies.

Formula 2: 70 parts of natural rubber, 30 parts of reclaimed rubber, 25 parts of vulcanized rubber powder, 3.5 parts of zinc oxide, 2.2 parts of stearic acid, 1 part of paraffin, 1 part of antioxidant D, 18 parts of carbon black N330, 12 parts of carbon black N774, 9 parts of light calcium carbonate, 7 parts of clay, 2.2 parts of pine tar, 1.8 parts of petroleum jelly, 0.7 parts of accelerator M, 0.4 parts of accelerator DM, 0.1 part of accelerator TMTD, 2 parts of sulfur; Total 185.9 copies.

Formula 3: 75 parts of natural rubber, 25 parts of reclaimed rubber, 55 parts of vulcanized rubber powder, 4 parts of zinc oxide, 2.7 parts of stearic acid, 1 part of paraffin, 1 part of antioxidant D, 35 parts of carbon black N330, 5 parts of light calcium carbonate, 3 parts of coal tar, 1.1 parts of accelerator M, 0.1 parts of accelerator TMTD, 2.3 parts of sulfur; Total 210.2 copies.

As a key component in direct contact with the road surface, the bicycle tire tread rubber should not only adapt to different road conditions, but also protect the inner tube, which directly affects the comfort and handling of riding, and it is necessary to reasonably design the bicycle tire tread rubber E4LYY826 formula; The vulcanized rubber powder is mixed with the tread rubber rubber of the bicycle outer tire, and the formula ratio must be flexibly adjusted according to the specific performance requirements and cost control objectives, and the production process conditions must be appropriately adjusted, so as to reduce the cost of more raw materials on the premise of ensuring the performance of the tread rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits