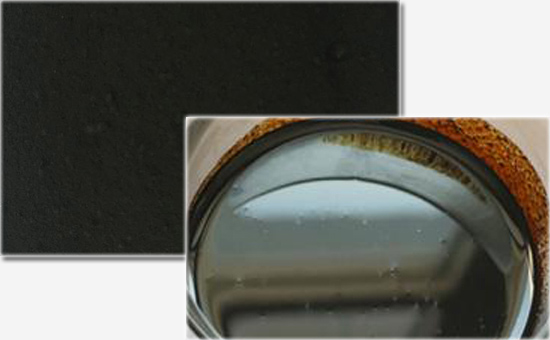

In the processing of rubber products, carbon black and rubber processing oil are two kinds of compounding agents which have great influence on the hardness of the rubber compound. Among them, carbon black can increase the hardness of the rubber compound in the production of rubber products, and the operating oil can reduce the hardness of the rubber compound; When the rubber product manufacturer adjusts the amount of carbon black or rubber oil to improve a certain index of the rubber compound, the relative offset relationship between the carbon black and the rubber operating oil can be understood, and the hardness of the rubber compound can be ensured.

In theory, 1 part of the operating oil can offset 1 part of carbon black; but carbon black is the most commonly used rubber reinforcing agent in the rubber products industry, and it has many types, including super wear-resistant carbon black, medium super wear-resistant carbon black, and high wear-resistant carbon. Black, semi-reinforcing carbon black, soft carbon black, etc., the molecular structure and reinforcing effect of different kinds of carbon black are very different, and the influence of carbon black on the hardness of rubber products is the surface area and internal structure of carbon black. Therefore, rubber product manufacturers need specific analysis when calculating the offset relationship between carbon black and operating oil:

1. In actual production, carbon black N330 is currently the most widely used high wear-resistant carbon black, which can improve the tensile strength, tear resistance, wear resistance and elasticity of rubber compound, carbon black used in rubber products. When having a very low or very high surface area and structure, it is necessary to follow the general principle derived from N330, that is, if a rubber product manufacturer needs to increase the processing performance of rubber products by adding 1 part of operating oil or achieve other purposes, it is necessary to increase 1 at the same time. The carbon black keeps the hardness of the rubber constant.

2. Carbon black N660 can give rubber products high tensile strength, tensile strength, tensile stress and good elasticity and flex resistance. It is often used in the production of rubber products such as tires, inner tubes, hoses, tapes and cables. This type of product has a high degree of structure and a slightly finer particle. The role of the product in rubber formulation is not the same as that of N330. Usually, 0.7 part of the operating oil can offset 1 part of carbon black, so as to keep the hardness of the rubber product unchanged; instead, use carbon black. The N734 rubber product requires 1.3 parts of rubber processing oil to offset one carbon black.

There are many kinds of rubbers, and there are countless kinds of natural rubber, synthetic rubber and reclaimed rubber products of different types, different brands and different indexes. Even the same kind of carbon black and rubber oil have different effects in different rubber products, so Under the premise of ensuring the hardness of rubber products, the other principles of rubber products should be adjusted by adjusting the amount of carbon black and rubber oil. It is necessary to follow the above principles, and it is necessary to study specific problems and adjust the performance and cost of rubber products. Formula.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits