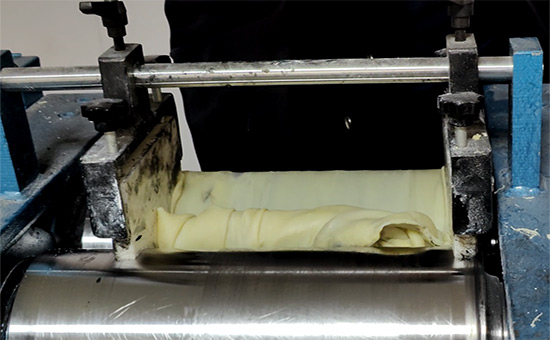

Rubber coated refers to the ease and characteristics of rubber adhering, wrapping or detaching from the surface of metal rollers during processing, especially on equipment such as openers, calenders or extruders. When the recycled rubber is mixed and tableted on the calender and calendered on the calender, the compound is required to have good rolling properties, otherwise it is difficult to operate smoothly. When using recycled rubber to produce rubber products, reasonable selection of rubber additives can effectively improve the rollability of recycled rubber.

1. Different varieties of rubber rolling properties are different

Factors such as molecular weight, molecular weight distribution, glass temperature, branching degree, and gel content of rubber affect the rolling properties of rubber. With the increase of molecular weight, when the molecular weight distribution is wide, the elongation ratio at break of the compound increases, and the roll wrapping performance of the rubber increases. Natural rubber and styrene-butadiene rubber are mixed at general operating temperature, and the roller performance is better; The glass temperature of butadiene rubber is low, the modulus is low, the rubber strength is small, and the rolling performance is not good. Most synthetic rubbers have low rubber strength and are not good for wrapping rollers.

Compared with natural rubber and synthetic rubber, recycled rubber is processed by physical and chemical processes such as crushing, heating, mechanical and chemical treatment, and the rubber molecular chain is destroyed, so the molecular chain of recycled rubber is relatively better and has a certain plasticity, which makes it easier for recycled rubber to fit with the roller on the refiner, and can better adhere to the surface of the roller, forming a continuous film, and showing better roll wrapping.

2. Which compound pairs can improve the recycled rubber coating performance

In actual production, the compound has high strength and good rolling performance. To improve the rolling performance of recycled rubber, carbon black, silica, hard terracotta, magnesium carbonate, calcium carbonate, etc., can improve the tensile strength and elongation ratio of recycled adhesive materials, and then improve the rollability of recycled rubber. The use of softeners such as high aromatic operating oil, pine tar, and coumaron resin helps to improve the adhesion of the compound, thereby improving the recycled coating properties.

3. Avoid using recycled adhesive compounds that are easy to remove rollers

Adding talcum powder to the compound will increase the tendency to roll off. Softeners such as stearic acid, stearate, wax, petroleum softeners, and ointments are easy to make the rubber roll off. To improve the rollability of recycled adhesive coatings, it is necessary to avoid the use of compounds that can easily cause roll detachment, and the amount of compounds must be minimized when used.

4. Appropriately adjust the production process parameters of recycled glue

When the recycled rubber is mixed on the refiner, the process conditions such as roll temperature, roll spacing and roll speed affect the rollability of the recycled rubber. If the roller temperature is too low, the recycled rubber will become hard and brittle, making it difficult to fit with the roller; If the roll temperature is too high, E5LYY320 recycled rubber may cause problems such as overheating oxidation and sticking rollers, which will also affect the roll wrapping effect; The appropriate roll temperature can maintain good softness and fluidity of the recycled glue, which is conducive to its uniform distribution and roll wrapping on the roller. Too large or too small roller spacing and uneven roll speed of the refiner will also adversely affect the rollability of the recycled rubber coating.

When using recycled rubber and raw rubber to produce rubber products, it is necessary to consider not only the rolling properties of recycled rubber and compounding agents, but also the rolling properties of rubber. Appropriate adjustment of rubber product formula and production process conditions can further improve the performance of recycled rubber overlay rollers.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits