Rubber conveyor belts are mainly used for the transportation of solid materials in fields such as mining, metallurgy, steel, coal, hydropower, building materials, chemical engineering, etc. They are made by bonding multiple layers of adhesive canvas together or using other tensile layer materials as the belt core, with an outer covering layer, and are formed and vulcanized. In actual production, the performance requirements of rubber conveyor belts vary greatly in different usage scenarios, and the raw materials used vary greatly. Recycled rubber, as a new raw material for reducing the cost of rubber products, can be used in conjunction with other raw materials to prepare conveyor belts and improve the overall performance of the finished product.

1. Common rubber raw materials for recycled rubber conveyor belts

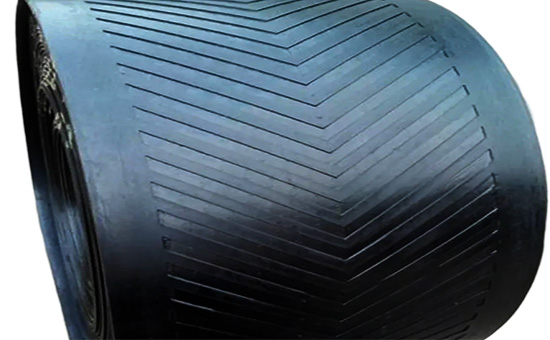

Rubber conveyor belts can be divided into ordinary conveyor belts, special performance conveyor belts, flame retardant conveyor belts, steel wire rope conveyor belts, etc. according to their usage. In actual production, ordinary rubber conveyor belts are mostly processed from natural rubber, butadiene rubber, styrene butadiene rubber, and other main raw materials; The heat-resistant conveyor belts in special performance conveyor belts can use chloroprene rubber, ethylene propylene rubber, etc., acid and alkali resistant conveyor belts can use butyl rubber, and oil resistant conveyor belts can use nitrile rubber, etc.

Recycled rubber, as a new type of rubber raw material that replaces high priced raw rubber, can be used alone or in combination with suitable varieties of raw rubber to produce rubber conveyor belts. For example, in natural rubber, butadiene rubber, and styrene butadiene rubber, an appropriate amount of latex recycled rubber 2SLYY421, tire recycled rubber, styrene butadiene rubber, etc. can be used. EPDM recycled rubber can be used in combination with ethylene propylene rubber to produce heat-resistant conveyor belts; Nitrile rubber can replace some nitrile rubber to produce oil resistant conveyor belts, and butyl rubber can be used together with butyl rubber and chloroprene rubber to produce acid and alkali resistant conveyor belts.

2. Common plastic raw materials for recycled rubber conveyor belts

In practical production, recycled rubber can not only be used in conjunction with natural rubber and various types of synthetic rubber to produce rubber conveyor belts, but also with plastics, commonly including polyvinyl chloride, polyethylene, and polytetrafluoroethylene. PVC has good flame retardancy; Polyethylene has a low price and can be added in small amounts to ordinary conveyor belt covering adhesive, further reducing costs; PTFE is heat resistant, oil resistant, aging resistant, chemical resistant, non combustible, and can be used in conjunction with natural rubber, synthetic rubber, and recycled rubber to produce heat-resistant rubber conveyor belts.

3. Common fiber materials for recycled rubber conveyor belts

By using recycled rubber to reduce the production cost of rubber conveyor belts, fiber materials can be used. Cotton fiber has low strength, good adhesion to rubber, and zero heat shrinkage rate. It is mostly used in low strength conveyor belts and high-temperature resistant conveyor belts. The commonly used chemical fibers in conveyor belts are polyester and nylon; Due to the low adhesion among nylon and polyester canvas and rubber, they are often immersed in glue to improve adhesion.

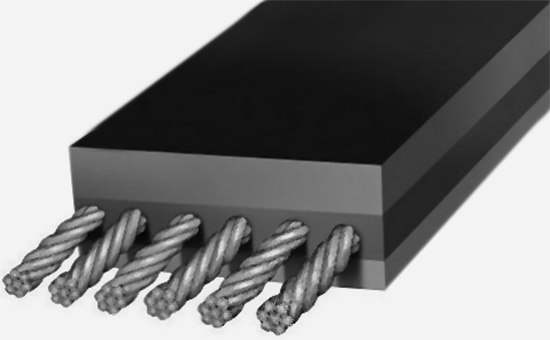

4. Common steel wire materials for recycled rubber conveyor belts

Steel wire materials have high strength and high temperature resistance. When using recycled rubber to replace some natural rubber and synthetic rubber to produce high-strength conveyor belts and high-temperature conveyor belts, steel wire reinforcement can be used. There are two types of steel wires used for conveyor belts: steel cord and steel wire rope. The ordinary structural type is composed of small steel wires of the same diameter combined. The new structural type is composed of outer steel wire layers composed of steel wires of different diameters, which have larger gaps than the ordinary type. During molding and vulcanization, the rubber material penetrates deeply into the interior of the steel wire rope, making the steel wire and rubber have good adhesion. There is no air inside, making it less prone to rusting, resulting in a longer service life of the conveyor belt.

When using recycled rubber to produce low-cost rubber conveyor belts, various rubber additives need to be combined, including vulcanization system, reinforcement filling system, softening and plasticizing system, anti-aging system additives, etc. The editor will continue to discuss relevant issues with you in the future.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits