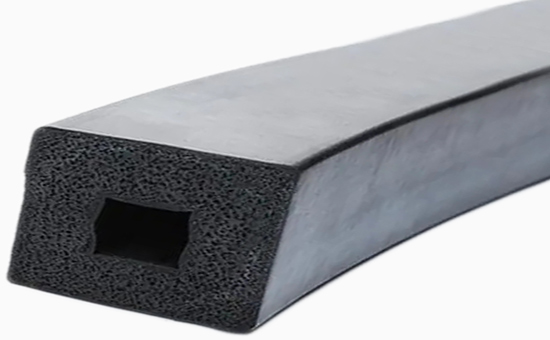

The rubber sealing strip can be divided into solid sealing strip, sponge sealing strip and composite sealing strip according to the material structure. The composite sealing strip can be divided into three categories: solid rubber and sponge rubber, solid rubber and metal, solid rubber and sponge rubber and metal. Sponge sealing strip has the characteristics of sponge rubber, low density, good elasticity, resistance to flexion, and good sealing and cushioning performance during use. Latex reclaimed rubber can be used in the production of sponge sealing strips, effectively reducing the cost of raw materials.

1. Application mode of latex regeneration adhesive in sponge sealing strip

In actual production, natural rubber, natural rubber/neoprene, natural rubber/styrene-butadiene rubber, natural rubber/neoprene/styrene-butadiene rubber, and natural rubber/neoprene/styrene-butadiene rubber can be used for processing sponge rubber sealing strips without special performance requirements for ozone resistance and aging resistance. The latex reclaimed rubber 2SLY313 can replace a certain proportion of natural rubber, and can be used alone or in combination with natural rubber and general synthetic rubber to produce sponge sealing strips; Adjust the formula properly to reduce the cost of raw rubber on the premise of ensuring the quality of rubber sealing strip.

2. Selection skills of latex regeneration adhesive for sponge sealing strip

When adding latex reclaimed rubber to the sponge rubber sealing strip to reduce the cost, the technical index, color, cost budget and other aspects of the sealing strip can be comprehensively considered. In actual production, it is recommended to select latex reclaimed rubber which is close to the indexes of sponge sealing strip to replace more parts of natural rubber; In addition, according to the color of the sponge sealing strip, select the latex reclaimed rubber with similar color, for example, the red natural latex reclaimed rubber is used for the red sponge sealing strip; In terms of cost, the price of black latex reclaimed rubber with the same index is lower than that of white latex reclaimed rubber. Therefore, black latex reclaimed rubber is recommended for black and dark sponge sealing strips.

3. Key points of formula design of foam sealing strip mixed with latex regeneration adhesive

When using latex reclaimed rubber alone or latex reclaimed rubber/natural rubber together to produce sponge sealing strips, the sulfur-accelerator system is mostly used to coordinate the curing rate and foaming rate with zinc oxide and stearic acid; The foaming system can use foaming agent AC, vaseline and foaming agent. It is recommended to use carbon black reinforcement and clay filling when using latex reclaimed rubber/natural rubber to produce foam sealing strips for automobiles; Use coumarone and engine oil to soften; In order to further improve the aging resistance of sponge sealing strips, in addition to the use of necessary anti-aging agents, a small amount of ultraviolet absorbent and paraffin can also be used.

The production cost of sponge sealing strips can be reduced by using latex recycled rubber. The rubber product manufacturer also needs to adjust the production process conditions properly. The editor will continue to discuss relevant issues with you later.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits