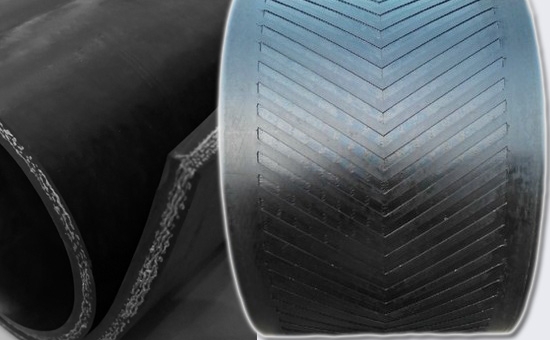

High-strength rubber conveyor belts generally use natural rubber as the main raw material or are used in combination with isoprene rubber. The purpose is to further improve the comprehensive index of high-strength conveyor belts. It is understood that the natural rubber conveyor belt has a strength of up to 35 MPa and excellent wear resistance and tear resistance. Replacing natural rubber with latex recycled rubber can significantly reduce the cost of raw materials for rubber products. Can it be used in the production of high-strength conveyor belts? How should it be applied?

1. Techniques for selecting latex recycled rubber in high-strength conveyor belts

The quality of latex recycled rubber on the market varies, and the strength of latex recycled rubber processed by different manufacturers and different waste materials varies greatly. When using latex recycled rubber to reduce the production cost of high-strength conveyor belts, in order to ensure that the mechanical strength of the rubber conveyor belt does not change, latex recycled rubber with high effective rubber hydrocarbon content must be selected. Latex recycled rubber, reducing more raw material costs.

Generally, latex recycled rubber processed with natural rubber waste rubber cups, rubber silk, and sub-brand natural rubber as raw materials has higher rubber content, better elasticity, and greater strength, and can be used to replace natural rubber in whole or in part. High-strength conveyor belt keeps physical properties unchanged.

2.Adding method of latex recycled rubber in high-strength conveyor belt

In theory, latex recycled rubber can directly replace natural rubber in a certain proportion for the production of various natural rubber products. When using latex recycled rubber to reduce the production cost of rubber conveyor belts using natural rubber2LLYY0317 as the main raw material, rubber product manufacturers can use latex recycled rubber with high rubber content alone, or use latex recycled rubber with natural rubber, or latex recycled rubber, Natural rubber and isoprene are used together.

It should be noted that when using latex recycled rubber to replace natural rubber, the replacement ratio must be reasonably determined according to the latex recycled rubber content. For example, 100% pure latex recycled rubber can replace natural rubber at a ratio of 1: 1. About 85% of the latex recycled rubber may replace natural rubber with a ratio of 1.3: 1.

At present, there are many types of rubber conveyor belts on the market. Many rubber conveyor belts will be mixed with a certain proportion of styrene butadiene rubber, butadiene rubber, etc. Due to the limitations of the two rubbers' own properties, the use of latex recycled rubber alone or completely to produce high When using a strong conveyor belt, it is necessary to strictly control the amount of styrene-butadiene rubber, butadiene rubber and other products in the formula to avoid the problem of excessive decline in the strength of the rubber conveyor belt caused by excessive use of synthetic rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits