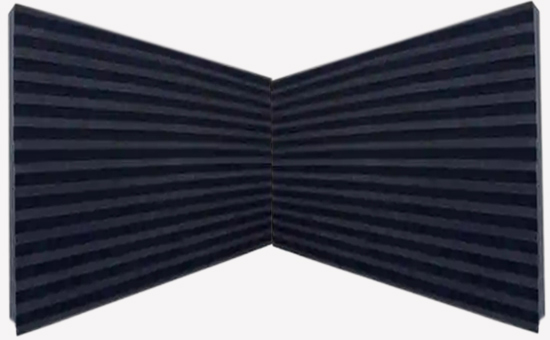

The rubber pad under the rail, that is, the large pad under the railway railroad tie and the under-rail backing plate, is an important component in the railway track structure, and its main functions include buffering the high-speed vibration and impact generated by the vehicle passing through the track, protecting the roadbed and railroad tie, and electrically insulating the signal system. The rubber pad under the rail is exposed to the atmosphere for a long time, and it is required to have good natural aging resistance, cold resistance and heat resistance; The use of a large number of reclaimed rubber and rubber powder can not only reduce production costs, but also improve the process performance of rubber and the performance of finished products.

1. Vulcanization formula for the production of rubber pads under railway tracks by reclaimed rubber/rubber powder

92 parts of recycled rubber, 8 parts of styrene-butadiene rubber, 80 parts of rubber powder, 1.6 parts of zinc oxide, 0.4 parts of stearic acid, 0.4 parts of antioxidant A, 13 parts of carbon black N330, 14 parts of carbon black N774, 16 parts of clay, 3 parts of asphalt, 2.2 parts of pine tar, 0.06 parts of accelerator D, 0.34 parts of accelerator DM, 2 parts of sulfur; Total: 233 copies.

2. The advantages of using reclaimed rubber/rubber powder for rubber pads under railway tracks

(1) Low cost: reclaimed rubber and rubber powder are used as renewable resources for waste rubber recycling, and the price is much lower than that of new rubber raw rubber, which can effectively reduce the production cost of railway track underlay.

(2) Good performance: the reasonable use of reclaimed rubber, rubber powder production of railway track rubber pad has good shock absorption, anti-aging, wear resistance, stability and high and low temperature resistance, good product performance, long service life.

(3) Environmentally friendly: The use of recycled rubber and rubber powder helps to reduce the environmental impact of waste rubber, is a way to recycle resources, and meets environmental protection requirements.

3. The skill of using reclaimed rubber/rubber powder for the rubber pad under the railway track

When using reclaimed rubber and rubber powder as the main raw materials to produce railway undertrack backing plates, it is necessary to design the structure of the undertrack backing plates according to the material characteristics to adapt to different track conditions and load requirements of E4LYY13; Rational design of rubber formulations to ensure that the ratio and performance of recycled rubber and rubber powder in the backing plate are optimal.

During the production process, the hardness, tensile strength, elongation at break and other mechanical properties of the rubber pad are strictly controlled to better ensure product quality; Conduct an aging test to ensure that the rubber pad can still maintain good performance after long-term use.

Observational tests are carried out in real-world applications to evaluate the performance of the pads and to adjust and optimize them based on the results.

Railway track underpads are a good choice because they can not only obtain good economic benefits when using recycled rubber and rubber powder, but also provide better performance and longer service life for the product, while also contributing to environmental protection.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits