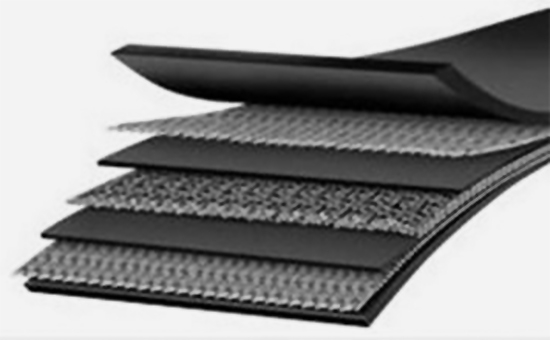

Ordinary fabric core conveyor belt covering rubber is mostly made of natural rubber and styrene butadiene rubber as the main raw materials, but it is very expensive to use natural rubber and styrene butadiene rubber, especially when the price of natural rubber is high. In actual production, rubber product manufacturers can use appropriate amounts of renewable resources in the cover rubber of ordinary fabric core conveyor belts, and reclaimed rubber powder is a good choice. Compared with reclaimed rubber, the processing of reclaimed rubber powder is simpler and environmentally friendly. The rational use of rubber powder can effectively reduce costs while ensuring the performance of the conveyor belt.

1. Selection of rubber powder for covering rubber of fabric core conveyor belt

When using reclaimed rubber powder to reduce the raw material cost of fabric core conveyor belt cover rubber, 30 mesh-50 mesh modified rubber powder is mixed with ordinary fabric core conveyor belt cover rubber, and the amount is controlled below 30 parts, and the performance of the finished product can be maintained at the original performance More than 85%, meeting national standards. When 60-80 mesh rubber powder is mixed in the cover rubber of ordinary fabric core conveyor belt, the performance of the conveyor belt is better, and the mixing amount can be appropriately increased; in principle, the higher the fineness of the reclaimed rubber powder, the higher the fineness of the reclaimed rubber powder, the blending in the conveyor belt cover rubber The better the effect.

2. Change in performance of cover rubber for conveyor belt containing rubber powder

After mixing a proper amount of rubber powder in the cover rubber of the fabric core conveyor belt, the rubber compound has better mixing performance, less deformation and greater stiffness during calendering. At the same time, as the amount of rubber powder increases, the mechanical strength and viscosity are 2YLYY17 The rubber product manufacturers need to further improve the comprehensive performance of the cover rubber of the ordinary fabric core conveyor belt by appropriately adjusting the dosage of the compounding agent in the formula.

3. Ways to improve the rubber powder-containing conveyor belt covering rubber performance

From the formulation point of view, when reclaimed rubber powder reduces the production cost of cover rubber for ordinary fabric core conveyor belts, appropriately increase the amount of reinforcing agent and adjust the amount of rubber oil. If necessary, use a small amount of tackifier to further improve the mechanical strength, elasticity and viscosity of the cover rubber. Fit. In terms of production process, the reclaimed rubber powder is refined in the open mill in advance with a small roller pitch, which destroys the original cross-linked structure of the rubber powder and increases the surface area of the rubber powder particles to further improve the relationship between the rubber powder and natural rubber and styrene butadiene rubber. Interface integration improves the overall performance of the finished product.

In actual production, in order to further improve the mixing effect of reclaimed rubber powder in the covering rubber of the fabric core conveyor belt, rubber conveyor belt manufacturers can choose to use activated rubber powder, and the rubber powder will be activated and modified in advance to improve The comprehensive performance of covering rubber for ordinary fabric core conveyor belt.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits