Replacing part of the original rubber in the rubber product formula can not only reduce the cost of the curtain rubber compound, but also improve the rolling rubber extrusion and extrusion performance, and increase the content of the reclaimed rubber in the formula to reduce the cost; There are some limitations on the performance characteristics of tire reclaimed rubber. In the rubber product formula, too much dosage will affect the performance of the product. Reasonable use of the modifier can increase the amount of tire reclaimed rubber in the curtain rubber within a certain range. Which kind of modifier should I choose for the curtain rubber? What are the effects of different kinds of modifiers on the performance of curtain rubber?

The rubber modifier can generally improve the rubber processing property and the physical properties of the vulcanizate. After being mixed in the rubber compound, the plasticity of the rubber and the uniform dispersion degree of the compounding agent can be obviously improved, thereby improving the resilience and elongation of the vulcanized rubber. Rate, chemical stability, tensile strength, and rubber extrusion performance.

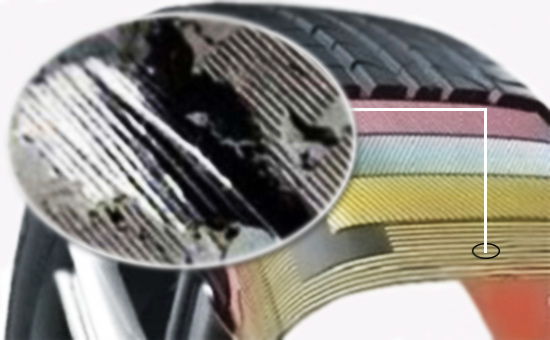

Studies have shown that in the formulation of the curtain rubber containing tire reclaimed rubber, the use of modifier can alleviate the impact of the increase of the amount of reclaimed rubber on the physical and mechanical properties of the vulcanizate. The modifier RU can improve the adhesion between the vulcanizate and the curtain. With the strength and heat resistance, the modifier ZVI can significantly improve the tensile strength of the vulcanizate containing the tire reclaimed rubber, but it will increase the hysteresis strength of the vulcanizate. At this time, a small amount of modifier VM can be further improved. The heat resistance of the curtain rubber reduces the hysteresis loss. Therefore, when the curtain rubber manufacturer incorporates the tire reclaimed rubber in the formulation, the modifiers RU, ZVI and VM can be used in a suitable ratio.

In the actual processing process, the amount of tire reclaimed rubber has the greatest influence on the tensile strength of the curtain rubber, and the constant tensile stress can maintain a high index in the range of wide reclaimed rubber by a reasonable modifier; therefore, the production of the curtain rubber The manufacturer can adjust the modifier ratio according to his actual situation, and maintain the physical properties without increasing the amount of tire reclaimed rubber.

The modifier RU, the modifier ZVI and the modifier VM are all commonly used modifiers in the rubber products of the tire reclaimed rubber in the early years, and the rubber compound can be obtained by chemical modification to obtain the reclaimed rubber-containing cord. In the rubber compound, it can be seen that the addition of a suitable modifier in the rubber product with wider use conditions can increase the content of the tire reclaimed rubber in the formulation and further reduce the production cost. At present, the quality of tire reclaimed rubber is continuously improving, and the types of modifier products are also increasing. Rubber products enterprises can use tire reclaimed rubber in more rubber products to improve economic efficiency.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits