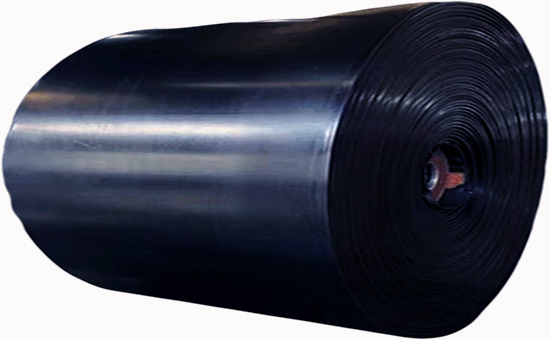

Heat-resistant rubber conveyor belt has good heat resistance, long-term use at a higher temperature is not easy to occur aging cracking, commonly used rubber raw materials are ethylene propylene rubber, neoprene rubber, styrene-butadiene rubber, butyl rubber, etc. Butyl reclaimed rubber retains the basic performance characteristics of butyl rubber, with good heat resistance and aging resistance, and can maintain good elasticity and strength in a high-temperature environment, so as to meet the basic needs of heat-resistant conveyor belts for rubber raw materials; The price of the product is much lower than that of the original rubber, and it can replace the appropriate proportion of butyl rubber to produce heat-resistant conveyor belts.

1. Reasonably determine the mixing method and addition ratio of butyl reclaimed rubber

Butyl reclaimed rubber can be used to produce heat-resistant rubber conveyor belts with butyl rubber and ethylene propylene rubber; Under normal circumstances, the addition of butyl reclaimed rubber should be controlled among 20% and 50%; In order to adjust the ratio through experimentation and production to achieve the best balance among cost and performance.

(1) When butyl reclaimed rubber and butyl rubber are used together to produce heat-resistant rubber conveyor belts, butyl reclaimed rubber is added to butyl rubber, which can reduce the cost of raw rubber and improve the problems of difficult rubber cutting, easy sticking rollers, and slow eating speed of mixing compound during butyl rubber processing; Adding butyl rubber to butyl reclaimed rubber can further improve the heat resistance and chemical stability of the finished product. In the combination of butyl rubber/reclaimed rubber to produce ordinary heat-resistant rubber conveyor belts, the proportion of butyl reclaimed rubber can be appropriately increased.

(2) The combination of butyl reclaimed rubber and EPDM rubber can improve the defects of butyl rubber softening after aging, and make the hardness change of the product more stable during the aging process. In some heat-resistant rubber conveyor belts used outdoors, EPDM rubber and butyl reclaimed rubber are appropriately added to improve the aging resistance of the conveyor belt in complex environments while reducing costs.

2. Reasonable design of heat-resistant conveyor belt formula containing butyl reclaimed rubber

When using butyl reclaimed rubber to prepare heat-resistant rubber conveyor belts, it is recommended to use low-sulfur or sulfur-free combinations, peroxide, and resin vulcanization systems. Improve the heat resistance of conveyor belts. The reinforcing system can be reinforced with carbon black N330, N550, mixed carbon black, etc., and filled with inorganic fillers silica, activated zinc oxide, magnesium oxide, etc. Paraffin oil, coal tar, chlorinated paraffin wax or solid coumaron, which has low volatility and high thermal decomposition temperature under high temperature E4LYY523, are used as softening plasticizers, and several softeners can be used together if necessary to improve the viscosity and heat resistance of butyl reclaimed rubber heat-resistant conveyor belt. Antioxidant MB, 2246, etc., to improve the heat aging performance of heat-resistant rubber conveyor belts.

3. Choosing appropriate processing equipment, such as advanced twin-screw extruder, open mixer and other equipment, can effectively improve the dispersion of butyl reclaimed rubber. Strict control of production process parameters, especially compounding and vulcanization processes. Insufficient vulcanization time will lead to insufficient cross-linking of the rubber compound, while excessive vulcanization will cause the material to become embrittle. The optimal vulcanization time and temperature can be determined through vulcanization curve analysis and formulation adjustments.

4. Butyl rubber/butyl reclaimed rubber is used to produce heat-resistant conveyor belts and wipe rubber vulcanization formula

65 parts of butyl rubber, 35 parts of butyl reclaimed rubber, 12 parts of zinc oxide, 1 part of stearic acid, 25 parts of carbon black N550, 13 parts of clay, 8 parts of polyisobutylene, 8.5 parts of paraffin oil, 8.5 parts of mineral oil, 4 parts of alkyl phenolic resin, 0.9 parts of diethyldithiocarbamate tellurium, 1.3 parts of accelerator DM, 0.8 parts of accelerator TMTD, 1 part of sulfur; A total of 184 copies.

When using butyl reclaimed rubber in heat-resistant rubber conveyor belts to reduce costs, it is also necessary to pay attention to the physical properties and stability of butyl reclaimed rubber, high-quality butyl reclaimed rubber is closer to the original rubber in terms of performance, with fewer impurities and high stability, such as Hongyun high-strength odorless butyl reclaimed rubber; The butyl reclaimed rubber produced by large-scale regular reclaimed rubber manufacturers has guaranteed quality and stability, and can better meet the process, performance requirements and long-term supply needs in the production of heat-resistant rubber conveyor belts; Avoid affecting normal production due to fluctuation in the quality of butyl reclaimed rubber or out of stock.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits