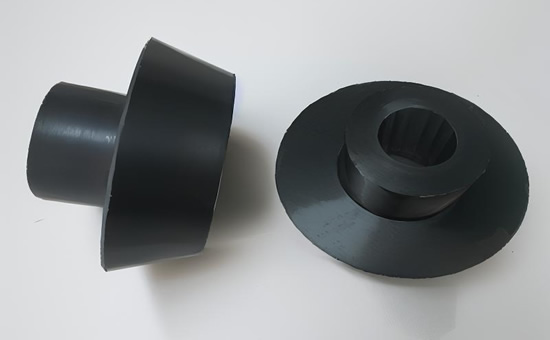

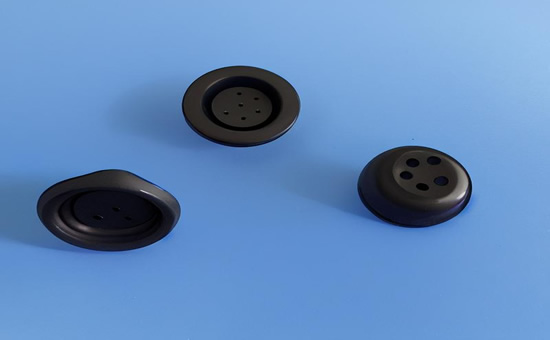

Butyl recycled rubber is an environmentally friendly material for sealing rubber stoppers, which has the characteristics of strong air tightness, heat resistance, ozone resistance, aging resistance, shock absorption, high strength, good hand elasticity, environmental protection and tastelessness. Butyl reclaimed rubber has a lower price than traditional butyl rubber. Under the premise of fierce competition in the current market, the use of HY butyl recycled rubber instead of butyl rubber has become an effective strategy to reduce costs.

The vulcanization formulation of butyl reclaimed rubber plays a key role in the production of sealing rubber stoppers. According to the available data and experimental results, the selection of efficient vulcanization formula is the prerequisite for ensuring the quality of rubber stoppers. The Hongyun butyl reclaimed rubber is mixed with additives such as plasticizers, fillers, accelerators, vulcanizing agents and antioxidants, and the performance requirements of butyl sealing rubber stoppers can be met by reasonably adjusting the proportion of additives and vulcanization temperature, such as air tightness, wear resistance, oil resistance and high temperature resistance.

In the processing of butyl reclaimed rubber production sealing rubber stoppers, the following points need to be paid attention to.

1. Ensure the quality and stability of butyl reclaimed rubber, select high-quality butyl reclaimed rubber suppliers, and carry out strict quality control.

2. Reasonably select the mold and process parameters of the rubber stopper to ensure the appearance accuracy of the product and ensure that the elastic modulus is consistent with the final product.

3. The vulcanizationprocess of butyl regenerated rubber requires accurate vulcanization temperature and time to ensure that the vulcanization degree of the rubber plug is appropriate to meet the ideal performance requirements, and the vulcanization test is necessary in the sample trial production stage.

The new raw material manufacturing technology of butyl sealing rubber stoppers, replacing butyl rubber with butyl reclaimed rubber YE3-802Y is an effective strategy to reduce costs. Through reasonable vulcanization formula and processing process, sealing rubber stoppers with excellent performance can be produced, which can not only reduce the cost of raw materials, but also meet the environmental protection requirements of resource recycling, improve the market competitiveness of products, and have broad development prospects.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits