Butyl reclaimed rubber has been widely used in the production of butyl sealing strips recently. Three years later, many companies reported that customers have a strong willingness to reduce costs. If they do not reduce costs, they may not be able to receive new orders. Some companies are forced to use butyl rubber Butyl reclaimed rubber, and some companies may have long used butyl reclaimed rubber to produce inner tubes and sealing strips. Butyl reclaimed rubber selects more than 900 waste butyl inner tubes as the main raw material. After picking and pulverizing, it is desulfurized by advanced desulfurization process and refined by 80 mesh filtration. It has good strength, high fineness, strong air tightness, Shock-absorbing, odorless, heat-resistant, ozone-resistant, aging-resistant, corrosion-resistant, and rich in elasticity, it can be used alone or in combination with butyl rubber to produce extruded or molded high-air-tight products.

Using HONGYUN butyl reclaimed rubber to produce hollow glass sealing strips has the following advantages:

1、Low cost. The price of butyl reclaimed rubber is lower than that of natural rubber and synthetic rubber, and the use of reclaimed rubber can reduce the production cost of sealing strips.

2、Stable physical properties. Butyl regenerated rubber has excellent weather resistance, ozone resistance and oil resistance. After the sealing strip is produced, these properties are stable and not easy to change during use.

3、 Good sealing. Butyl rubber has high elasticity and good rebound performance, and has strong sealing performance under hysteresis load conditions, which can effectively seal hollow glass.

4、 The environment is friendly. The use of butyl reclaimed rubber embodies the concept of resource reuse and energy saving and emission reduction, which has little impact on the environment and meets the requirements of sustainable development.

5、 Good process performance. Butyl recycled rubber has good compatibility with general formulation additives, and it is easy to realize optimized formulation design and stable production process, and the product quality is controllable.

6、 High capacity utilization. Butyl reclaimed rubber does not require plastication, which is conducive to improving the capacity utilization rate of the production line and reducing the unit product cost.

Butyl reclaimed rubber 26E3Y5y sealing strip vulcanization formula and process: 50 parts of butyl reclaimed rubber, 80 parts of light calcium carbonate, 15 parts of zinc oxide, 0.8 parts of stearic acid, 10 parts of N774 carbon black, 9 parts of engine oil, DM Accelerator 0.3 part, TMTD accelerator 1 part, sulfur 1.1 part; vulcanization condition: 145 ℃, vulcanization time is determined according to product size.

The use of butyl reclaimed rubber should also pay attention to the following issues:

1、 The components and properties of butyl reclaimed rubber have a large range of fluctuations, and the raw materials must be strictly controlled to meet the performance requirements.

2、 The mechanical strength of butyl reclaimed rubber is slightly low, so it is necessary to increase the amount of reinforcing filler in the formula appropriately.

3、 Butyl reclaimed rubber is a secondary material, which may contain particles and impurities. Special attention should be paid to the rubber filtration process.

4、 Butyl reclaimed rubber contains some carbon black, plasticizer, etc. If the amount of additives is used according to butyl rubber, it is easy to be too high, and the formula design needs to be optimized.

In general, the use of butyl reclaimed rubber to produce air-glass sealing strips has greater cost and environmental advantages. However, there are also problems such as large changes in raw material properties, low mechanical strength, and difficult processing control. This requires targeted optimization in terms of raw material selection, formula design, and process control to ensure that product quality meets technical requirements.

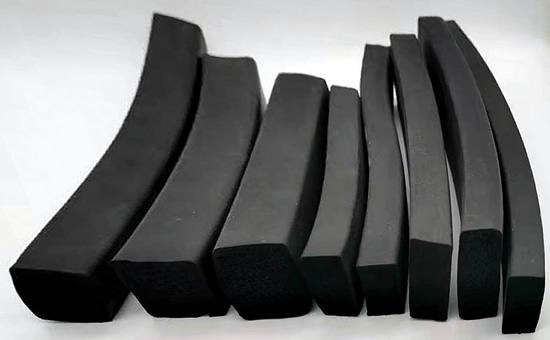

The main process steps of using butyl reclaimed rubber to produce hollow glass sealing strips are as follows:

1、 Purchase reclaimed rubber. Select butyl reclaimed rubber with stable quality, resistivity and weather resistance indicators that meet the requirements, and conduct factory inspection.

2、 Mixing. Weigh reclaimed rubber, carbon black, vulcanizing agent, accelerator and other raw materials according to the formula, and mix them on the internal mixer until they meet the requirements.

3、 Filter. The mixed rubber is filtered 1-2 times with a thin-plate wire mesh to remove impurities and particles and improve the appearance and performance of butyl regenerated rubber.

4、 Mixed sulfur. Add vulcanizing agent and accelerator to the filtered butyl regenerated rubber on the open mill to make the rubber additives fully react with the rubber, and pay attention to the control of mixing time.

5、 Forming. The vulcanizate is molded into a film with a certain width and thickness through the unloading of the open mill. If molding, you need to cut strips. Cut the kneaded rubber sheet into rubber strips of specified length and width through a strip cutter for subsequent determination.

6、 Vulcanization. Rubber strips with consistent appearance dimensions are made by molding or extrusion and vulcanized. Pay attention to the coordination of vulcanization temperature and vulcanization time.

7、 Inspection and packaging. The finished rubber sealing strip is inspected for degree of vulcanization, size, appearance, etc., and is packaged after passing the test.

8、 Storage. Store the packaged rubber seals in a cool and ventilated warehouse to prevent the surface from tarnishing.

The main process of producing butyl rubber sealing strips is mixing-filtering-vulcanization-molding-cutting-vulcanization-inspection and packaging-storage and other steps. This is a relatively typical rubber processing process. The main point is to strictly control the parameters of each process, especially the vulcanization time and degree of vulcanization, and focus on strengthening the filtration process to ensure product quality. It is necessary to strictly follow the operating procedures to reduce process deviation and ensure product stability. Compared with butyl raw rubber, the use of butyl reclaimed rubber also needs to pay attention to the particularity of reclaimed rubber, and optimize the material selection, formula and process control, such as selecting raw materials with stable performance, appropriately increasing the reinforcement ratio, and optimizing additives. Dosage, etc., this is also the key point. Only by careful design and strict control on the basis of comprehensive consideration of the characteristics of reclaimed rubber can high-quality products with cost advantages be realized.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits