The function of rubber shoes is to bond the upper and the bottom, protect the upper from wear, is the most deformed part of the rubber shoes, the rubber material is required to have good flexural resistance and aging resistance, generally processed with natural rubber as the main raw material, and the appropriate amount of reclaimed rubber can effectively reduce the cost of raw materials. In actual production, the glue content of rubber shoe bib is slightly higher than that of other parts, so which reclaimed rubber is better to use? How to design a rubber shoe bib formula containing reclaimed rubber?

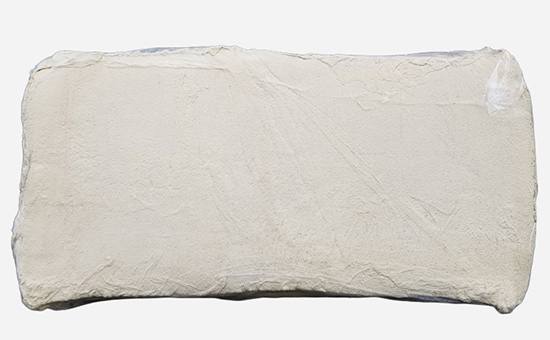

1. Natural rubber/light-colored reclaimed rubber to produce army green sliver rubber formula

90 parts of natural rubber, 10 parts of light-colored reclaimed rubber, 5 parts of zinc oxide, 1 part of stearic acid, 0.8 parts of antioxidant MB, 0.2 parts of antioxidant H, 0.3 parts of paraffin, 55 parts of clay, 0.1 parts of carbon black N660, 0.1 parts of pigment green, 9 parts of coumaron resin, 3 parts of petroleum jelly, 9 parts of liquid coumaron resin, 1.5 parts of accelerator M, 0.1 parts of accelerator D, 0.5 parts of accelerator TMTD, 2.4 parts of sulfur; Total 188 copies.

2. Natural rubber/butadiene rubber/light-colored reclaimed rubber to produce army green sliver rubber formula

75 parts of natural rubber, 15 parts of butadiene rubber, 10 parts of light-colored reclaimed rubber, 5 parts of zinc oxide, 2.7 parts of stearic acid, 0.5 parts of antioxidant MB, 0.5 parts of antioxidant 4010, 55 parts of clay, 0.1 parts of carbon black N660, 0.1 parts of pigment green, 1.8 parts of chrome yellow, 9 parts of coumaron resin, 9 parts of liquid coumaron resin, 2.7 parts of petroleum jelly, 0.5 parts of accelerator M, 0.9 parts of accelerator D, 1.2 parts of accelerator NOBS, 1.5 parts of sulfur; Total 190.5 copies.

3. Key points of the design of the vulcanization formula of rubber bib glue mixed with reclaimed rubber

(1) Raw rubber system: When using reclaimed rubber to reduce the production cost of rubber shoe strip rubber, light-colored and colored strip rubber generally choose light-colored film, such as white crepe sheet, white reclaimed rubber, and choose non-polluting synthetic glue, such as BR9000, when used in combination with synthetic rubber.

(2) Vulcanization system: natural rubber/reclaimed rubber is used in combination to produce rubber shoe sliver glue, which mostly uses sulfur-accelerator system, such as accelerator M/DM/D with sulfur; When zinc oxide and stearic acid are used as active agents, it is necessary to control the amount of stearic acid to avoid spraying.

(3) Packing system: to improve the fatigue resistance of natural rubber/reclaimed rubber sand rubb, it is recommended to use carbon black with weak reinforcing in the black sand and fill a large number of inert fillers; It is generally recommended to use calcium carbonate, clay, etc. for light-colored fences, and an appropriate amount of lithop powder can be used when necessary.

(4) Protection system: light-colored swafers are generally used with antioxidants MB, 2246, 264, SPC, etc., and dark-colored swafers can be used with antioxidants A, 4010NA and H. It should be noted that accelerator M has an inhibitory effect on the aging performance of antioxidant MB, and accelerator D can play a role in promoting improvement. When using direct zinc oxide as a filler, it is recommended to use MB, or use it in combination with antioxidant SP to improve the flexural fatigue resistance of the swath rubber.

(5) Softening system: light-colored sand generally uses petroleum jelly, taking into account the anti-aging effect; The dark sand is made of coumarone resin, industrial grease, etc.; According to the operation requirements, spindle oil E5LYY16, light diesel oil or calcium-based grease can be used as mixing operation aids. It should be noted that Vaseline can prevent calcium carbonate from spraying, and excessive dosage can easily cause the product to lose its luster.

(6) Colorant: When natural rubber/reclaimed rubber is used to produce light-colored and colored rubber shoe strip glue, it is necessary to choose a colorant with strong tinting strength, bright color, no migration, no discoloration, high temperature resistance, sunlight resistance, steam resistance and other characteristics; To improve the color vibrancy, you can add 5-20 parts of titanium dioxide or zinc barium white. Organic colorants are not easy to disperse evenly, in order to avoid color difference, it is recommended to make masterbatch.

When using reclaimed rubber instead of part of natural rubber to produce rubber shoe bib rubber, it is necessary to choose the appropriate reclaimed rubber according to actual needs, such as white latex reclaimed rubber can be used for color and light color sliver rubber, which is easy to match and not easy to change color; Rationally design the formula of the strip rubber, appropriately adjust the production process parameters, and further reduce the cost of raw materials on the premise of ensuring the performance of the finished product; The editor will continue to discuss related issues with you.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits