With the enhancement of environmental awareness and the importance of resource recycling, black latex recycled rubber is widely used in the production of rubber products as a renewable resource. Compared to traditional natural rubber, black latex recycled rubber has many advantages, such as outstanding price-performance ratio, environmental friendliness and sustainability. Black latex HONGYUN recycled rubber is a recycled rubber material obtained by recycling and reprocessing waste rubber products. It has the following features and advantages:

1. Outstanding cost performance: Compared with natural rubber, black latex recycled rubber has lower production cost and can provide more competitive prices. This makes it ideal for replacing some natural rubber.

2. Environmental protection: During the production process of black latex reclaimed rubber, it can reduce the dependence on natural resources, reduce energy consumption and environmental pollution. At the same time, the recycling of used rubber products also helps to reduce the environmental pressure caused by landfill and incineration.

3. Sustainability: The reprocessing process of black latex reclaimed rubber can be reused many times, extending the life of the material and realizing the recycling of resources. This helps reduce the demand for natural rubber and alleviates resource shortages.

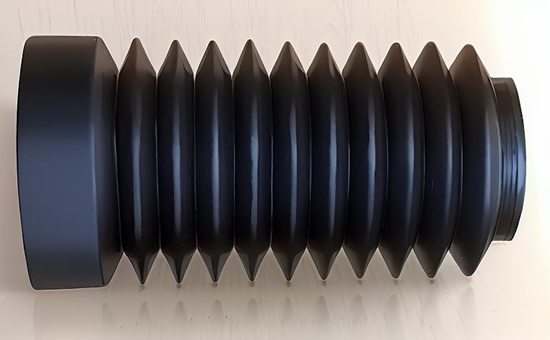

Black HY latex reclaimed rubber produces vulcanization formulations for electric vehicle dust jackets:

85% black latex reclaimed glue 10kg, top ultrafine reclaimed rubber 40kg, carbon black 1.5kg, talc 8kg, paraffin 0.3kg, stearic acid 0.7kg, zinc oxide 0.65kg, polyethylene glycol 0.5kg, 4010 antioxidant 0.2kg, comaron resin 0.3 to kg, CZ accelerator 0.2kg, DM accelerator 0.23kg, TMTD accelerator 0.06kg, sulfur 0.5kg The formula is for reference only, and the actual application needs to be adjusted and optimized according to Y23-724Y specific requirements.

The compoundingprocess of black latex reclaimed rubber is similar to that of conventional rubber, but the following points need to be noted:

Raw material preparation: Black latex reclaimed rubber, sulfur, accelerator, antioxidant, active agent and carbon black and other raw materials are prepared according to the formula ratio.

Rubber mixer operation: gradually add raw materials to the rubber mixer, and control the temperature and speed of the rubber mixer. Under normal circumstances, the mixing temperature is 80-100 °C, and the speed is 30-40rpm.

Rubber refining time: According to experimental data and experience, control the rubber refining time, generally 8-15 minutes.

Vulcanization processing: put the mixed rubber into the vulcanizing machine to control the vulcanization temperature and vulcanization time. According to the formula requirements, the vulcanization temperature is generally 150 °C, and the vulcanization time is 30 minutes.

The use of black latex recycled rubber instead of natural rubber to produce electric vehicle dust jackets has outstanding advantages such as cost performance, environmental protection and sustainability. Through reasonable vulcanization formula and rubber refining process, electric vehicle dust jacket products that meet the requirements can be produced. It should be noted that specific formula and process parameters need to be adjusted and optimized according to the actual situation to ensure the stability of product quality and performance.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits