Rubber sealing products are simple in structure, easy to use and reliable in performance, which is a major category of rubber industrial products, and is widely used in various vehicles, vehicles, chemical pipelines, instrumentation and other fields. Tire reclaimed rubber is a renewable resource processed by crushing, desulfurization, refining, molding and other processes of waste tire rubber, with good elasticity, wear resistance, tear resistance and aging resistance, which can be used in the production of rubber sealing products to reduce raw material costs and production energy consumption.

1. Performance requirements of rubber sealing products

Rubber sealing products are used in various types of machinery, which require rubber to have certain mechanical strength, elasticity and low compression set; Rubber O-rings, gaskets, gaskets, sealing strips and other sealing products used under static conditions are required to have good compression deformation resistance, medium resistance, aging resistance and other properties; Rubber products used under dynamic conditions also require rubber compounds to have good wear resistance, flexural resistance, etc.

High-strength reclaimed rubber can produce rubber sealing products with high requirements for strength, wear resistance E4LYY66; For rubber sealing products that require a smooth surface, such as rubber sealing strips, it is recommended to choose ultra-fine tire reclaimed rubber; When rubber sealing products need to be engraved on the surface, the migration of tire reclaimed rubber needs to be considered, and it is recommended to choose not to migrate tire regeneration; When using tire reclaimed rubber for rubber sealing products used indoors for a long time, it is recommended to choose environmentally friendly reclaimed rubber and odorless reclaimed rubber that have passed environmental protection certification.

2. What rubber sealing products can be produced by tire reclaimed rubber

(1) Rubber sealing strip

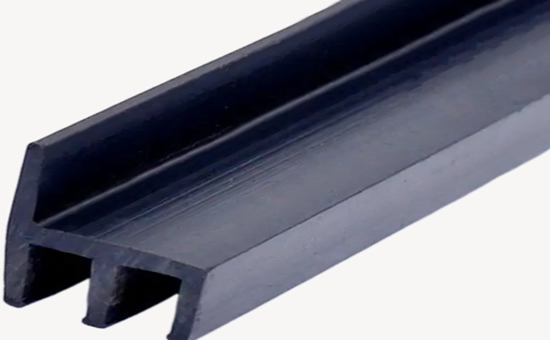

Rubber sealing strip is a long elastic sealing element with rubber material as the main component, which is mainly used to fill and seal the gap among two parts to prevent the leakage or penetration of liquids, gases, dust and other substances. Tire reclaimed rubber can be used in combination with natural rubber, styrene-butadiene rubber, butadiene rubber and other rubber in appropriate proportions to produce building door and window seals, automobile seals (used for sealing automobile doors and windows, car body gaps) and transportation seals.

(2) All kinds of rubber sealing gasket gaskets

Rubber sealing gaskets and gaskets are sealing elements processed from rubber as the main raw material, which are mainly used to fill or block the gap among two or more mechanical parts and prevent the leakage of liquid, gas or dust, and are widely used in industrial and civil fields. Tire reclaimed rubber can be used alone or in combination with natural rubber, styrene-butadiene rubber, butadiene rubber, etc. to produce various types of rubber gaskets and gaskets, such as water pipe gaskets, water gaskets, cement pipe sealing rings, etc., effectively reducing the cost of raw materials.

3. A large number of tire reclaimed rubber is used to produce low-cost rubber sealing strip vulcanization formula

15 parts of natural rubber, 10 parts of butadiene rubber, 75 parts of tire reclaimed rubber, 2 parts of zinc oxide, 0.5 parts of stearic acid, 1 part of antioxidant A, 0.8 parts of paraffin, 10 parts of carbon black N330, 25 parts of light calcium carbonate, 10 parts of engine oil, 10 parts of industrial fat, 0.25 parts of accelerator D, 0.4 parts of accelerator DM, 1.35 parts of accelerator M, 0.05 parts of accelerator TMTD, 1.95 parts of sulfur; Total 163.3 copies.

When using tire reclaimed rubber to produce rubber sealing products, it is not only necessary to select the appropriate reclaimed rubber according to different application scenarios and performance requirements, reasonably design the formula, but also need to appropriately adjust the production process conditions, such as mixing time, mixing temperature, vulcanization time, vulcanization temperature, vulcanization pressure, etc., and the follow-up editor will discuss relevant issues with you.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits